- Joined

- Mar 12, 2014

- Messages

- 1,531

Repaired a Jeep suspension link over the weekend. The snap-ring had popped out and damaged the groove so I machined a new one and then cut the damaged one off the link and welded the newly machined one on. I then beadblasted and painted it as close as I could come with some paint I had on the shelf.

Here is the one with the damaged end link. I quickly welded the snap ring in place a few weeks ago until I could find time to build a replacement end link.

Old one cut off.

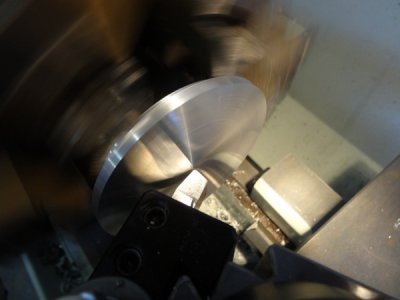

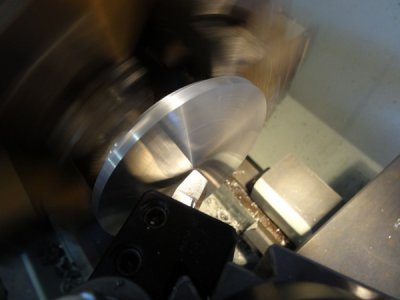

Machining a new end link. Had to use my custom made snap-ring grooving tool that I just ground from HSS.

Machining complete.

Test fit of the bushings and sphrerical ball prior to welding.

Proper fit-up is crucial to a strong weld and overall strength of the part. Especially being a suspension component.

Weld completed.

After bead blasting, priming and painting.

Here is the one with the damaged end link. I quickly welded the snap ring in place a few weeks ago until I could find time to build a replacement end link.

Old one cut off.

Machining a new end link. Had to use my custom made snap-ring grooving tool that I just ground from HSS.

Machining complete.

Test fit of the bushings and sphrerical ball prior to welding.

Proper fit-up is crucial to a strong weld and overall strength of the part. Especially being a suspension component.

Weld completed.

After bead blasting, priming and painting.