- Joined

- Jun 11, 2013

- Messages

- 731

Nice job ! What did you use or do to remove the rust & clean up the table ? I have a very similar unit that has similar rusting.

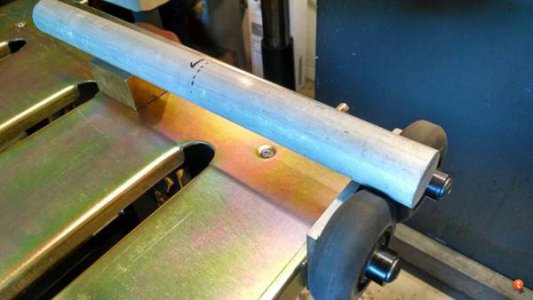

3in1 penetrant with brown scotchbrite, then stoned the table. Wire brush on a drill to clean up most of the rest.