AP ...

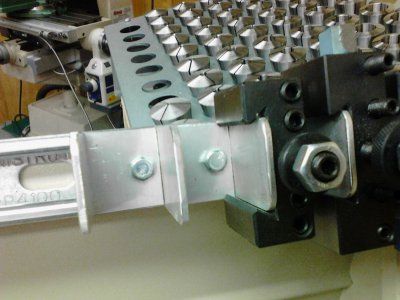

The square is 20 mm

While the blank was on the lathe I drilled a 19 mm hole

After clamping in the rotary table via a 3 jaw

I centered the 19mm hole under my mill center.

Using a colleted end mill 1/4 "

I moved the table the calculated amount to end up at 20 mm semi-finished square size

The remaining material in the corners was then filled to fit the square heads.

* In order to undo these wheel studs the 3/4 drive socket and breaker bar needed an additional 6 foot pipe as leverage. They were tight.

Only problem I see is that your 12 point socket is going to have a hard time not breaking if you get onto some really tough nuts. I've worked on some old military vehicles that a six foot cheater wouldn't start to budge.

- - - Updated - - -

AP ...

The square is 20 mm

While the blank was on the lathe I drilled a 19 mm hole

After clamping in the rotary table via a 3 jaw

I centered the 19mm hole under my mill center.

Using a colleted end mill 1/4 "

I moved the table the calculated amount to end up at 20 mm semi-finished square size

The remaining material in the corners was then filled to fit the square heads.

* In order to undo these wheel studs the 3/4 drive socket and breaker bar needed an additional 6 foot pipe as leverage. They were tight.

Only problem I see is that your 12 point socket is going to have a hard time not breaking if you get onto some really tough nuts. I've worked on some old military vehicles that a six foot cheater wouldn't start to budge.