- Joined

- Dec 29, 2013

- Messages

- 284

this is my first project post, so go easy... i'm new, ha.

my biggest complaint about my new PM-932 is that the y-axis hand wheel limits the table travel. its hits the limit switch for the power feed and i'm sure it would hit the table if that switch wasn't three.

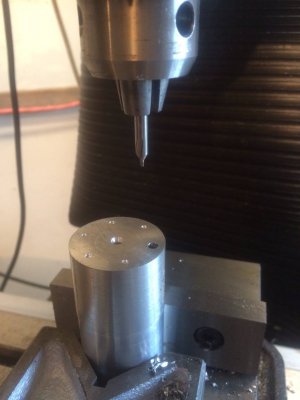

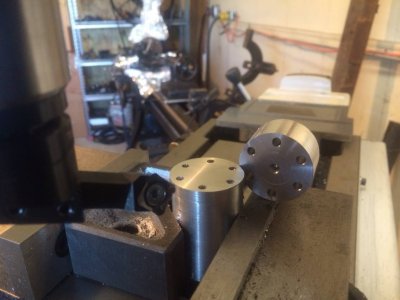

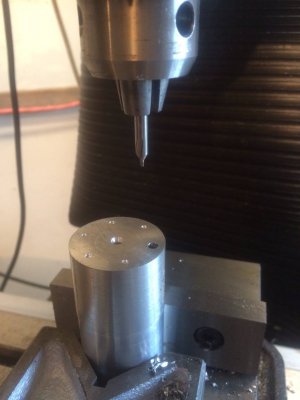

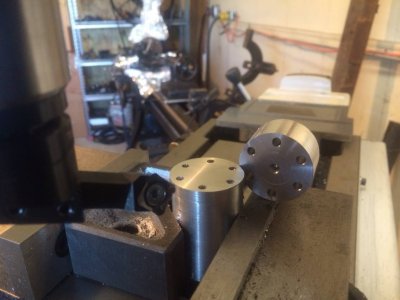

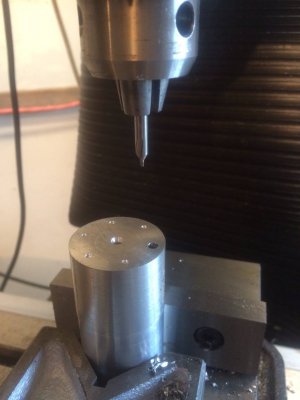

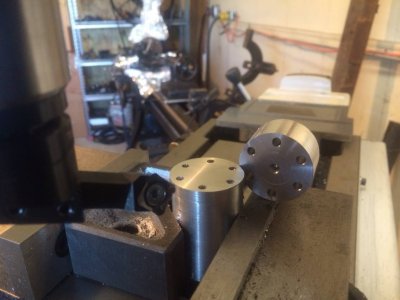

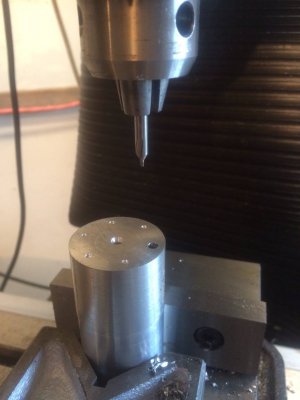

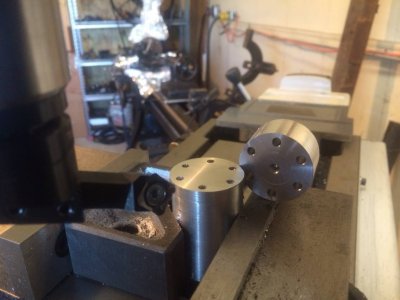

so, today i started working on a new handle. the first piece (what i did today) has to match the 3 lug interface of the lead screw. without having a dividing head or rotary table, here is what i came up with.

what do ya think? i drilled the six holes and simply "clocked" the piece around with pins as i milled away.

- - - Updated - - -

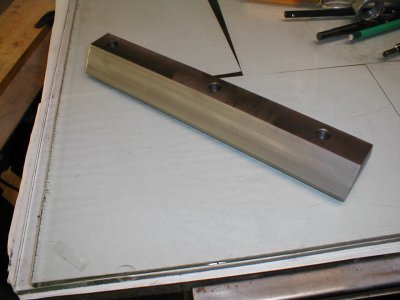

finished piece and then placed on the current hand wheel to show fitment. now i just need to make the handle part and attach it to the center piece. probably just drill the same hole pattern and bolt it together with m5 countersunk bolts. since getting my countersink set, i really like the custom touch something so simple provides.

my biggest complaint about my new PM-932 is that the y-axis hand wheel limits the table travel. its hits the limit switch for the power feed and i'm sure it would hit the table if that switch wasn't three.

so, today i started working on a new handle. the first piece (what i did today) has to match the 3 lug interface of the lead screw. without having a dividing head or rotary table, here is what i came up with.

what do ya think? i drilled the six holes and simply "clocked" the piece around with pins as i milled away.

- - - Updated - - -

finished piece and then placed on the current hand wheel to show fitment. now i just need to make the handle part and attach it to the center piece. probably just drill the same hole pattern and bolt it together with m5 countersunk bolts. since getting my countersink set, i really like the custom touch something so simple provides.