I have two of those too, Cactus Farmer, but they're strictly manually operated.

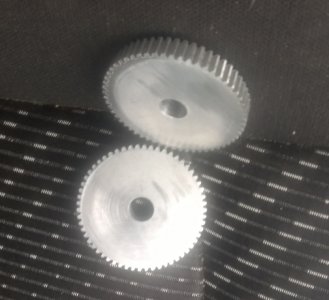

When I got the gear out, it looked horrible. Every tooth was totally chewed in half. Some idiot must have engaged the feed lever and tapping half-nut simultaneously. I'm going to have to give him such a noogie that he'll never do it again.

When I got the gear out, it looked horrible. Every tooth was totally chewed in half. Some idiot must have engaged the feed lever and tapping half-nut simultaneously. I'm going to have to give him such a noogie that he'll never do it again.