Hi Jack,

Some more pictures of your lathe drive system would help.

How many steps do you have in the head-stock pulleys?

How is it being driven? (ie. how many pulley steps in your drive train?)

I suspect that maybe you have not found the back-gear mechanism?!?!?

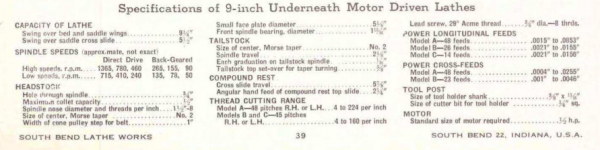

From the manual I posted in post #19 of this thread:

View attachment 135299

View attachment 135299

(Sorry about the image sizes something wrong and it will not let me post full-size images!!!!)

(The second one is a "thumbnail view" that you should be able to click on to open bigger!)

It lists 6 direct speeds and 6 "back-gear" speeds.

Typically, it uses a shaft the site behind the headstock main shaft (thus the term "backgear").

You need to do two things to enable it:

- dis-engage a small lock on the headstock pulley that locks it to the headstock shaft

- move a lever that drives a cam that bring the gears on the back-gear shaft into mate with the headstock gears

I will try to locate some info for your specific lathe and post back with some pictures.

-brino