- Joined

- Jul 30, 2017

- Messages

- 476

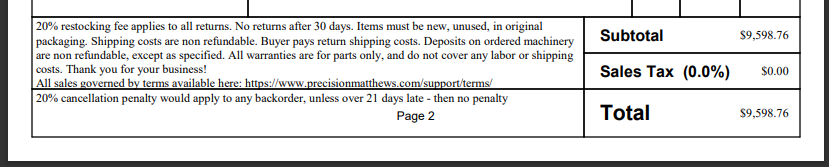

Just going by what this invoice says, Restocking fees apply to all returns, It doesn't state on hold or shipped just says all returns & deposits on ordered machinery are none refundable... My Lathe is on back order till mid April.

I've had no Issues with Precision Matthews, I have talked on the phone with them a few times, they always answer question, are polite and have patience, same can be said about grizzly as well.

I don't blame anyone but my self, if I buy a sail boat and I don't know how to sail, Its on Me. I was under the impression I had to get BXA size for this lathe, ill call PM now to verify..!

I called and talked to John at Precision Matthews and explained my issue, he was very patient with me, I specifically asked if I can use my AXA QCTP and tooling, he said no AXA is not an option.

He went on to say I can use all my old tooling, but in order to meet the center tool height of the new lathe by design a BXA QCTP will be required.. he said he knows there are some clever people out there that modify AXA's to work with this lathe, but the BXA is what I need... I left it with that.

John put all my question to rest and BXA it is. Ill give away the AXA stuff but keep the tooling.

I appreciate all the input and help from every one and now have a direction to head towards. thank you..!

I've had no Issues with Precision Matthews, I have talked on the phone with them a few times, they always answer question, are polite and have patience, same can be said about grizzly as well.

I don't blame anyone but my self, if I buy a sail boat and I don't know how to sail, Its on Me. I was under the impression I had to get BXA size for this lathe, ill call PM now to verify..!

I called and talked to John at Precision Matthews and explained my issue, he was very patient with me, I specifically asked if I can use my AXA QCTP and tooling, he said no AXA is not an option.

He went on to say I can use all my old tooling, but in order to meet the center tool height of the new lathe by design a BXA QCTP will be required.. he said he knows there are some clever people out there that modify AXA's to work with this lathe, but the BXA is what I need... I left it with that.

John put all my question to rest and BXA it is. Ill give away the AXA stuff but keep the tooling.

I appreciate all the input and help from every one and now have a direction to head towards. thank you..!

Last edited: