- Joined

- Jun 12, 2014

- Messages

- 4,810

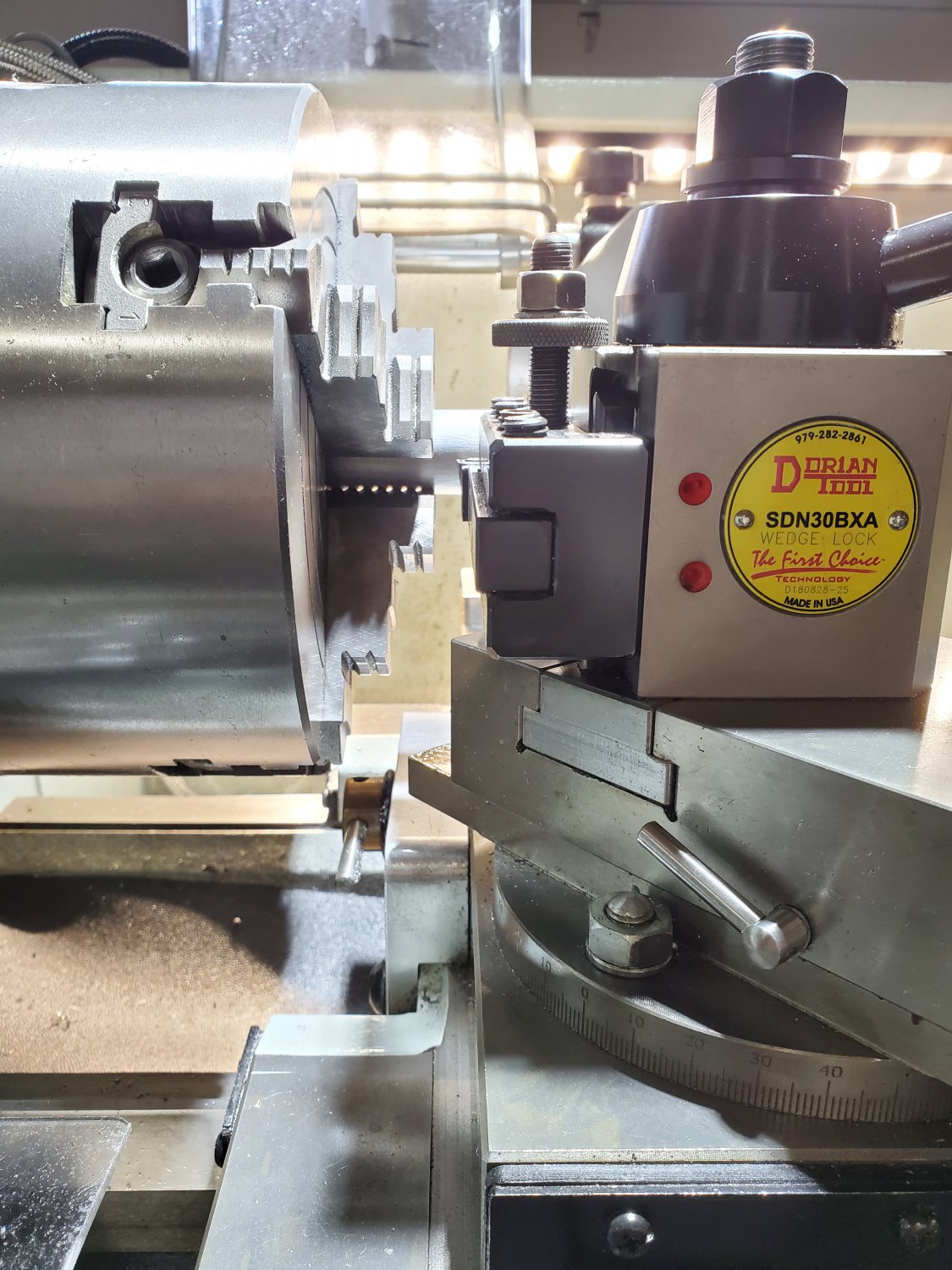

AXA tooling will work on a 1236 lathe in most cases. You may need to shim the QCTP if you cannot get enough height, removing the compound going with a solid tool post circumvents the height issue. If you need the compound and do not shim the QCTP then it will change the cutter heights. I have seem shims under the QCTP, but could be another point for rotation. If using the compound, then you end up with issues like below where the compound could hit the chuck before the cutter, in particular if the jaws are reversed. The other area where there can be a clearance issue is with a live center in the tailstock and/or if you add a digital caliper/scale to the tailstock, I had this issue on my 1340GT and had to get a CNC live center with a smaller body. It is not that it won't work, it is just that as PM indicated that a BXA is a better choice. I also use the oversized BXA holders in some cases for 3/4" index holders that I want more rigidity like knurling.