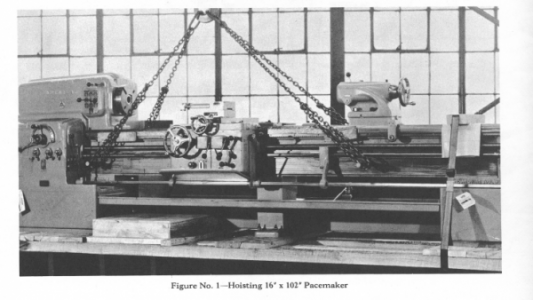

It wouldn’t be the method I use but.... I’m sure I read on Practical M website’s rigging forum this exact same subject with many people responding that they do lift lathes by the headstock. I doubt it did any damage.

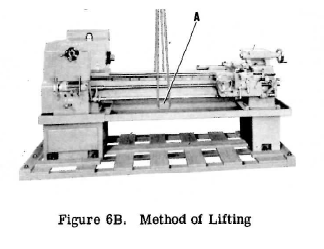

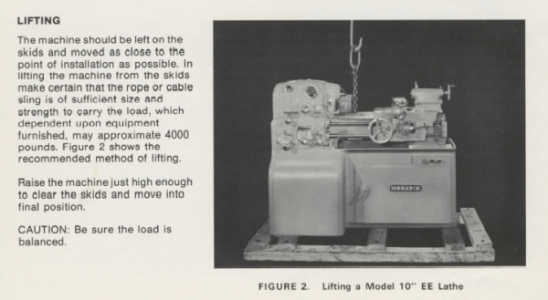

As far as the opinion that Clausing has it wrong with their recommendation of where to lift.... I seriously doubt that being the case. As beefy as the bed of the 5900 lathe is.... I’m sure lifting a 1200 # load under the cast iron bed does absolutely no damage at all. The manuals and lathes came out in the 50’s and nowhere is there a person who even claims that their lathe got damaged by following those instructions.

As far as the opinion that Clausing has it wrong with their recommendation of where to lift.... I seriously doubt that being the case. As beefy as the bed of the 5900 lathe is.... I’m sure lifting a 1200 # load under the cast iron bed does absolutely no damage at all. The manuals and lathes came out in the 50’s and nowhere is there a person who even claims that their lathe got damaged by following those instructions.