-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New (to me) Logan 200

- Thread starter TomKro

- Start date

I think I have some seat belt webbing that would make a nice strap wrench - need to give that a try.

I'm still scrounging up electric parts for controls. Went to the local big box store and they had none of the smaller size 4 wire SO cord. I need to stop at a real electric supply house, or just do the mail order thing. Sometimes one shipping charge works out better than 3 or 4 trips to all the local suppliers.

I'm still scrounging up electric parts for controls. Went to the local big box store and they had none of the smaller size 4 wire SO cord. I need to stop at a real electric supply house, or just do the mail order thing. Sometimes one shipping charge works out better than 3 or 4 trips to all the local suppliers.

Connected the camera to the computer last night, so here's an update on the world's slowest lathe rehab.

Tailstock was badly worn, but two separate e-bay purchases has it working nicely. I replaced the broken hand wheel, and found a used barrel with good threads at a good price. The tailstock will require shimming to height, but it's nice and tight now.

I also found a really nice 4 jaw chuck from a fellow up in Jersey.

I had to jack up the pedestal base, and thought I'd use something nicer than a paver block and a chunk of wood. Just happened to have a small plastic tub that matched the base OD perfectly. I had a bunch of old mortar mix, so....

The motor and VFD have been bench tested, and the 3/4 HP motor squeezed into it's new home. It's a 3 phase D56 frame. The motor J box interfered with the adjustment hardware, so it had to be padded up a bit.

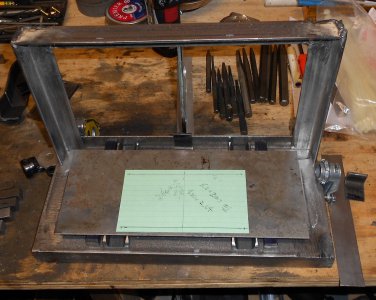

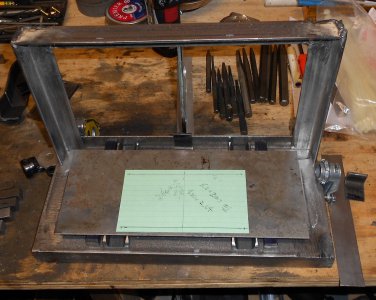

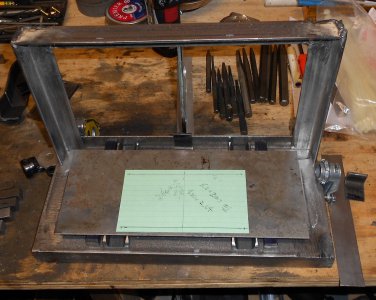

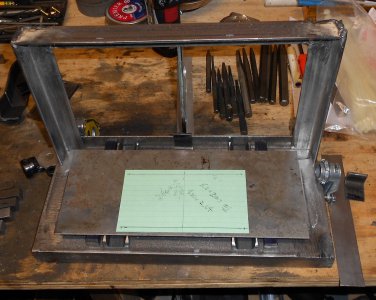

I'm still working the electric box. I decided to make it up out of small hot rolled shapes on hand. Not sure if I just wanted the cutting, fitting and welding practice, or if I'm just too darn cheep. Trying to keep the enclosure small, but the layout is turning into somewhat of a Rubic's Cube. Still some welding to finish up the frame. I hope it works out to be sort of a clamshell design, with the face of the VFD exposed when the door is opened (the vertical frame in the pic will be the back of the box). I did buy the remote keypad with the VFD, so maybe I'm just getting silly. Hopefully it works out and doesn't end up in the scrap bin.

Another year or two and this thing will be done!

Tailstock was badly worn, but two separate e-bay purchases has it working nicely. I replaced the broken hand wheel, and found a used barrel with good threads at a good price. The tailstock will require shimming to height, but it's nice and tight now.

I also found a really nice 4 jaw chuck from a fellow up in Jersey.

I had to jack up the pedestal base, and thought I'd use something nicer than a paver block and a chunk of wood. Just happened to have a small plastic tub that matched the base OD perfectly. I had a bunch of old mortar mix, so....

The motor and VFD have been bench tested, and the 3/4 HP motor squeezed into it's new home. It's a 3 phase D56 frame. The motor J box interfered with the adjustment hardware, so it had to be padded up a bit.

I'm still working the electric box. I decided to make it up out of small hot rolled shapes on hand. Not sure if I just wanted the cutting, fitting and welding practice, or if I'm just too darn cheep. Trying to keep the enclosure small, but the layout is turning into somewhat of a Rubic's Cube. Still some welding to finish up the frame. I hope it works out to be sort of a clamshell design, with the face of the VFD exposed when the door is opened (the vertical frame in the pic will be the back of the box). I did buy the remote keypad with the VFD, so maybe I'm just getting silly. Hopefully it works out and doesn't end up in the scrap bin.

Another year or two and this thing will be done!

- Joined

- Jul 27, 2013

- Messages

- 295

I'd say we're neck and neck!... so here's an update on the world's slowest lathe rehab.

M

Mister Ed

Forum Guest

Register Today

I'd say we're neck and neck!

LOL ... if I ever start a thread about rebuilding my lathe, I sure hope one of you two jump in and stop me!! I know mine would be a multi year project as well.

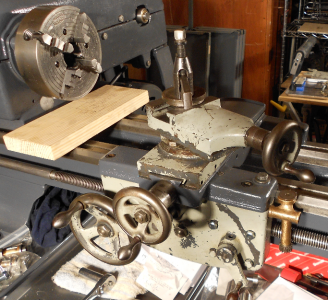

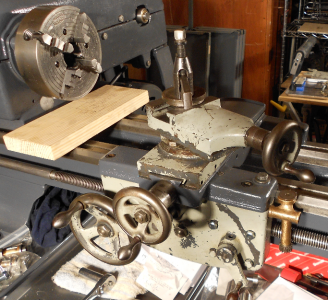

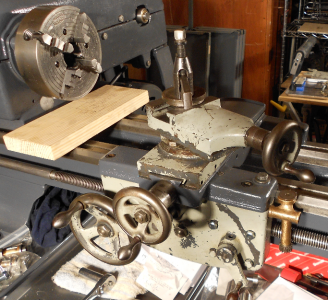

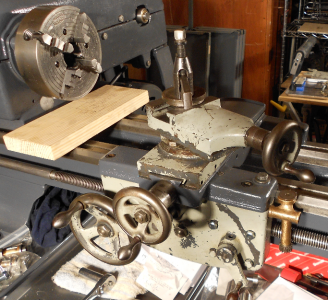

Progress update.

I really wanted to get some more painting done, but the weather wasn't cooperating.

Since I was mixing and matching donor carriage parts I thought it best to make sure everything works OK before stripping the paint.

The cross feed screw worked out real nice. Only about 3 or 4 thousands of total play. Compound is a little looser, maybe 6 or 7 on the dial. Right now it's still ugly, but all is snug and smooth.

The 3" height boost (the tubing and rubber feet) appears to be just about right, so I'm a happy camper.

Just have to find some time to get back to that electric box...

I really wanted to get some more painting done, but the weather wasn't cooperating.

Since I was mixing and matching donor carriage parts I thought it best to make sure everything works OK before stripping the paint.

The cross feed screw worked out real nice. Only about 3 or 4 thousands of total play. Compound is a little looser, maybe 6 or 7 on the dial. Right now it's still ugly, but all is snug and smooth.

The 3" height boost (the tubing and rubber feet) appears to be just about right, so I'm a happy camper.

Just have to find some time to get back to that electric box...

- Joined

- Jul 27, 2013

- Messages

- 295

Ha!

Nice to see you're back to plugging away. Maybe philanthropy agrees with you!!! :LOL:

Is your half nut handle mounted that way? I believe they are supposed to be at the top to gain a little help from gravity. I had to go and look, to be honest, as I have recently had the same question on mine. Factory photos show it at the top.

Nice to see you're back to plugging away. Maybe philanthropy agrees with you!!! :LOL:

Is your half nut handle mounted that way? I believe they are supposed to be at the top to gain a little help from gravity. I had to go and look, to be honest, as I have recently had the same question on mine. Factory photos show it at the top.

Thanks for the info. That sure makes sense. I wish I would have thought to check a picture yesterday.

I was having all kinds of trouble with that handle and pin. I just couldn't get it to line up. Finally realized I had to remove the half nut frame from the apron, in order to push in a little bit on the cam plate/shaft. Extra "practice" should help it go faster next time.

I was having all kinds of trouble with that handle and pin. I just couldn't get it to line up. Finally realized I had to remove the half nut frame from the apron, in order to push in a little bit on the cam plate/shaft. Extra "practice" should help it go faster next time.