- Joined

- Apr 23, 2018

- Messages

- 6,830

I want to take a moment to share with you where so much of the magic happens. No, it's not the boudoir, but it is under a blanket. A Russian-made flaxen fire blanket! Such mystery, such provocation! Such unfinished walls!

It's a HF parts washer, complete with genuine 1990's contingency stickers. I've owned this thing for awhile, like since I was 20. It gets a solid green light for HF tools.

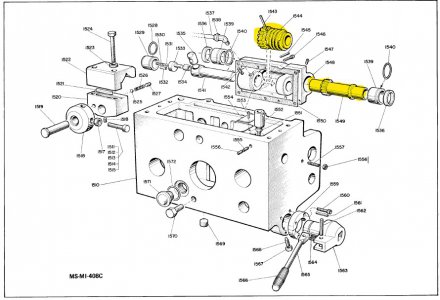

What's the big deal, anyway? Well, it's one of my most heavily used tools, and people like photos. Let's look under the hood:

Okay, no surprises there. But if you've never seen the inside of a parts washer, now you have.

Here's the tip of the month: Buy only washing solvent for cleaning parts, never fuel. Fuel is full of rank stinky toxic junk because it's end of pipeline cut. It doesn't need to be pure for any reason. Cleaning solvent, aka stoddard solvent, is highly refined compared to kerosene, white gas, lamp oil, or whatever cockamaime hillbilly stuff your grandpa used. It's made for workers to hand wash parts with, so it is low odor, dries clean, and is generally pure straight chain hydrocarbon chains with around 8 to 12 carbons, no branching, no cyclics, no heteroatoms. Because of that, it is very low toxicity, with the 8-hour exposure limit way up around 600 ppm. For a 12 carbon chain, that equates to like 3 grams per cubic meter. With a vapor pressure around 5 mm Hg, it only evaporates when heated. Washed parts dry in the sunlight and leave no oily residue. The capacity for 5 gallons of solvent is unreal, I've cleaned numerous junkyard transmissions, engines, pumps, gearboxes, on and on, and still don't notice much degradation in performance. It lasts for several years, and disposes as waste oil. So it really pays for itself in the long run.

It's a HF parts washer, complete with genuine 1990's contingency stickers. I've owned this thing for awhile, like since I was 20. It gets a solid green light for HF tools.

What's the big deal, anyway? Well, it's one of my most heavily used tools, and people like photos. Let's look under the hood:

Okay, no surprises there. But if you've never seen the inside of a parts washer, now you have.

Here's the tip of the month: Buy only washing solvent for cleaning parts, never fuel. Fuel is full of rank stinky toxic junk because it's end of pipeline cut. It doesn't need to be pure for any reason. Cleaning solvent, aka stoddard solvent, is highly refined compared to kerosene, white gas, lamp oil, or whatever cockamaime hillbilly stuff your grandpa used. It's made for workers to hand wash parts with, so it is low odor, dries clean, and is generally pure straight chain hydrocarbon chains with around 8 to 12 carbons, no branching, no cyclics, no heteroatoms. Because of that, it is very low toxicity, with the 8-hour exposure limit way up around 600 ppm. For a 12 carbon chain, that equates to like 3 grams per cubic meter. With a vapor pressure around 5 mm Hg, it only evaporates when heated. Washed parts dry in the sunlight and leave no oily residue. The capacity for 5 gallons of solvent is unreal, I've cleaned numerous junkyard transmissions, engines, pumps, gearboxes, on and on, and still don't notice much degradation in performance. It lasts for several years, and disposes as waste oil. So it really pays for itself in the long run.