B

Bill Gruby

Forum Guest

Register Today

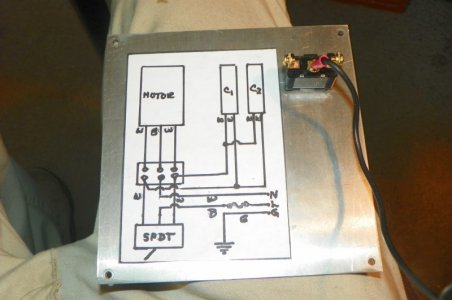

Today I am going to to finish the electrical end all the way to the motor hook up. That will leave just 3 wires to be connected at final assembly. See you later.

"Billy G"

"Billy G"