Put an Ad on Craigslist for a free treadmill last night, got a call today.

Was able to take it down enough to get in the car,

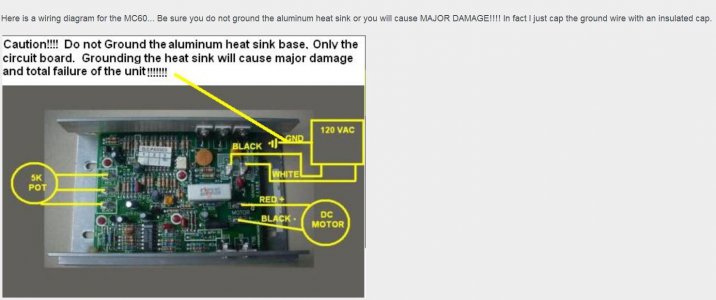

I will do some searching, but anyone know how to wire this board?

It is a model KK6039T.

Looks like this one on e bay.

I should have been a little more mindful when I took it apart, but the lady was in a hurry.

It even had a pot with it, and a On off switch I can re purpose.

There is a group of 3, S1 S2 S3, I am betting is for the pot.

Then there is L1 and L2 together? Line one and line 2?

Then there is a A1 and a A 2 and they are spread apart.

The motor looks nice, almost looks like a 56 frame motor, and the fan (2 actually) is mounted on the shaft. I am thinking the fans can stay on there.

or will they just pull dust and sawdust into my motor?

The shaft is double, and is a nice shaft, 5/8" with key way.

I did not measure the mounting holes yet, but I bet it will line up. If not, it will be a easy matter to adapt.

board looks like this.

I see there are trim pots on the board.

One says "Torque"

crank that one all the way up;right?..................LOL

Let me know if that picture is too big, I will edit it.

I will have to take a picture of the motor later.

I can't find one like it on line.

like I said, its cool looking, looks like a baby 56 frame.