- Joined

- Mar 14, 2013

- Messages

- 736

Then you needn't worry about it.

If it works you're ok.

Right.

Then the heat sink for that board must not be hot. It's a design tradeoff. Some engineers will do it one way, some the other.

Thank You John.

So, IOW's, I should be able to, (won't sue you if something happens............LOL...........) ground the heat sink, and/or mount the heat sink to the DP frame and ground the DP Frame?

BTY,

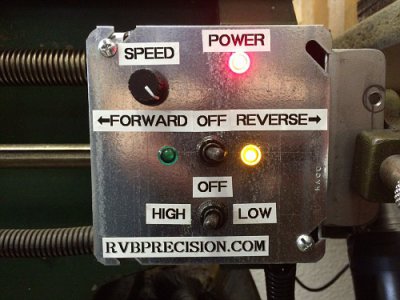

got it mounted last night, just have the board hanging there for now, but like I was saying,

The mounting on this TM motor is Sweet!!

"Baby 56 frame" for sure.

Mounting bracket on motor matched right up with DP motor mount,

5/8" keyed double ended shaft, (keyed on both shafts) So a off the shelf pulley was able to be used.

And was able to use my same belt.

What is nice about this (double ended key way'ed shafts) is, as it looks like the motor brushes are in there at an angle, l would say it's best to run it in the factory designed direction only.

But if I needed the other direction, I could just flip the motor end for end 180*.

One thing I did notice, at real slow speed, (sort of a crawl) I can stall the spindle by hand, and the controller does not try to compensate for the stall.

Maybe I can try tweaking the IR compensation pot for this.

But so far I think it is pretty cool.

As far as breaking the center wire to the pot, so I can re-start at the speed I stopped at, I don't think I will. It is pretty easy to just judge the speed I had it set to before.

One thing I did adjust was the Max speed, I don't think I need it quite as fast as the board was allowing.