- Joined

- Nov 27, 2012

- Messages

- 7,855

I agree with Will. About half my AXA tool holders are Aloris, the other half Phase II. Very little physical difference in the tool holder body and Phase II uses okay set screws. The height adjusters are far superior on the Aloris holders and they are consistently hardened but beyond that, no, not worth buying Aloris or Dorian just to hold a tool. A small lathe just doesn't have the guts to even remotely stress a tool holder so I would go cheap on these things.

Agreed, I'm a believer that the quality of the tool post is more important than the holders.

Yep the ones I have from Shars are indentical to the Phase II, even down to the engraving except Phase II uses better set screws & says Phase II on them. I used to buy them WT Tool cause they came unmarked (no branding). Then they started coming with the Shars logo on them. The bulk of mine that I got from Shars were before they started putting their logo on them. Not sure if they are still from the same factory. Lathemaster's QCTP & holders also came from the same factory except their AXA holder came premilled down for their 8x14 lathe. I had the LM QCTP AXA on my HF 8x14 before I got a DTM.

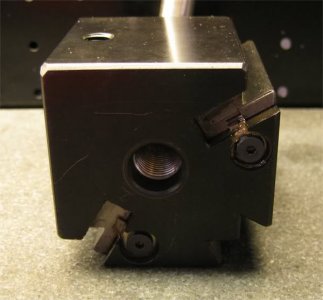

I wish I could have gotten a DTM in BXA for my current lathe. The guys who made DTM used to work for Aloris & claimed to have improved on Aloris' design. They were even located in the same city. Lol. I never took the DTM apart but what I noticed different were guides for the wedges. IIRC the owner eventually retired or something like that. I got the DTM AXA from a guy who purchased the remaining stock from DTM but the TP75a (BXA) QCTPs were long gone. No matter, I'm happy with my Dorian.

As you said the AXA holders were the same dimensions as Aloris but for some reason the import BXAs from that same manufacturer were not. No big deal but I always wondered why. The CDCO ones are from a different manufacturer. The quality of their holders are not as good but their price is the cheapest to be found.