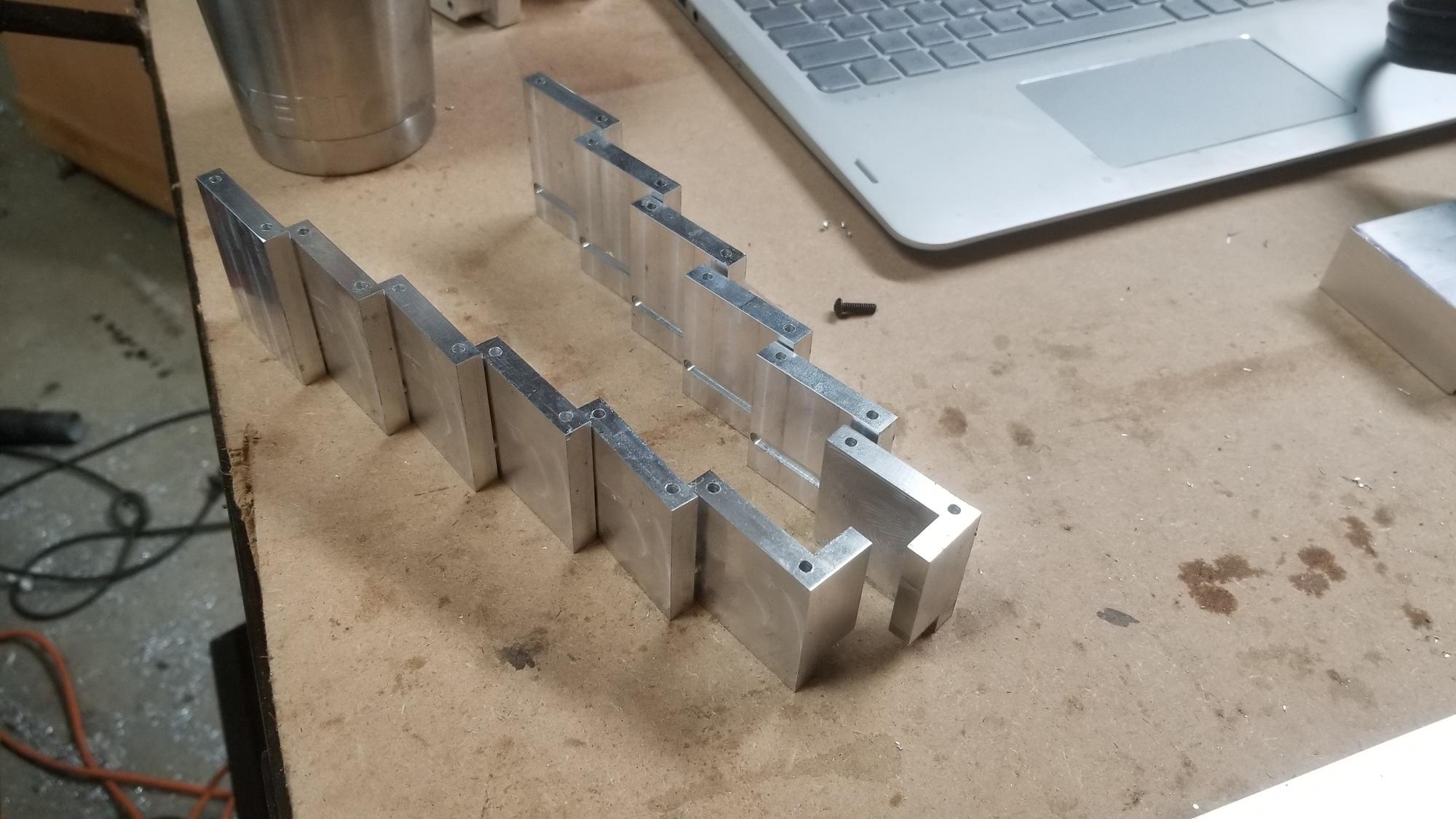

I finished putting the way covers together and I am hopeful. They stay together well look to fit pretty well too. A few of the sheets aren't completely straight, so the spacing between each segment isn't uniform on top. I may have to go with a more sturdy material if that turns out to be a problem. There is always the option of remaking the sheets out of steel instead of aluminum. The sliding action is good. They index off each other correctly and as long as I slide them out and in straight, I had no trouble with them binding up. Occasionally, one of the segments did pop out of the slot, so I am thinking the .025" shims will be needed on the sides to keep them centered up and prevent the parts from separating.

One other thing I had not considered was the noise they would make when you open and close them. It sounded a lot like those heavy wood blinds on windows that go *ClackClackClackClackClackClack" when you open them. I have a feeling when I have the Y axis going at 500 IPM, that could get obnoxious. If it does, I may stick a small rubber bumper or something in the slot to keep that noise to a minimum.

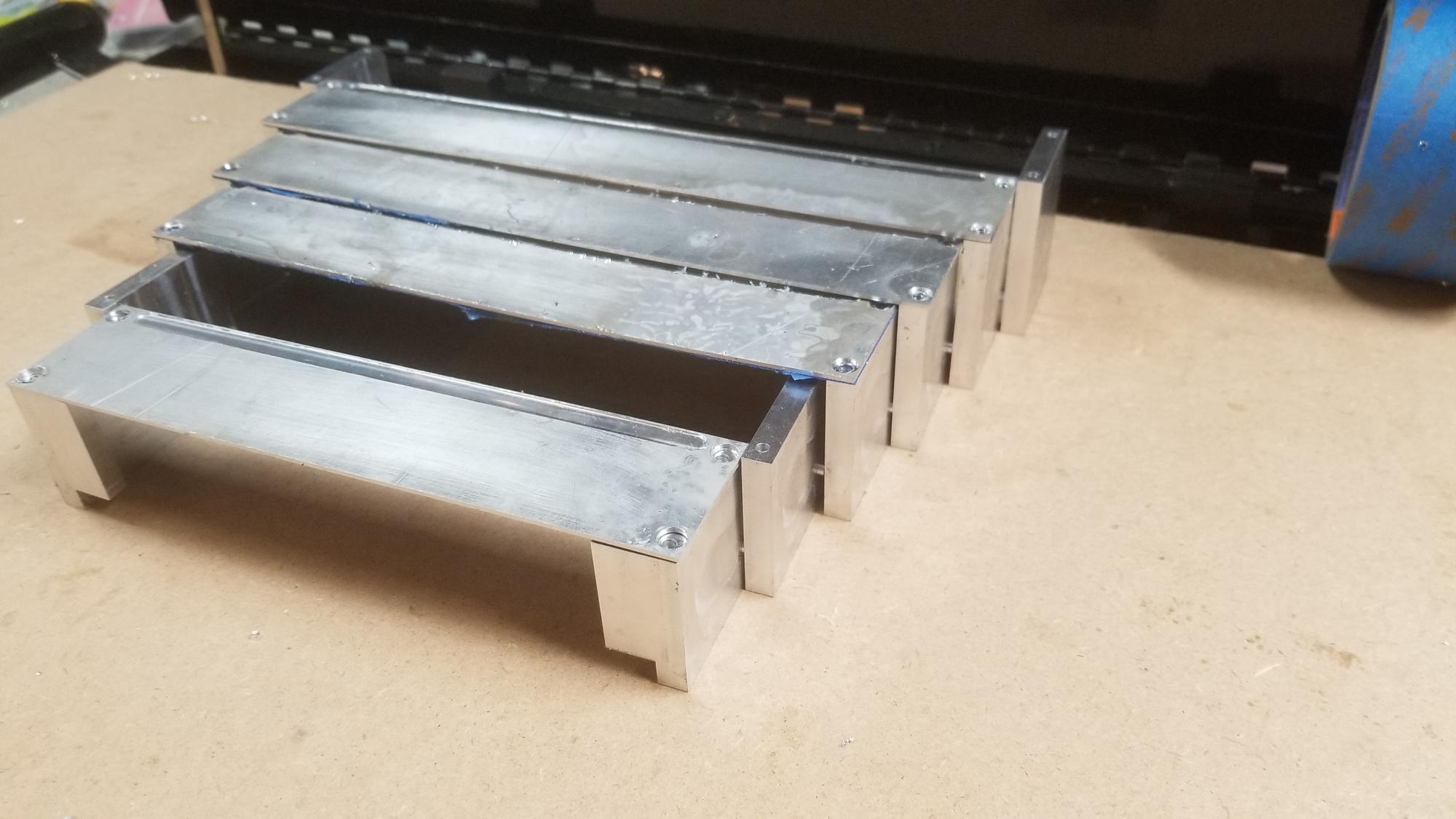

Here they are in all their assembled glory.

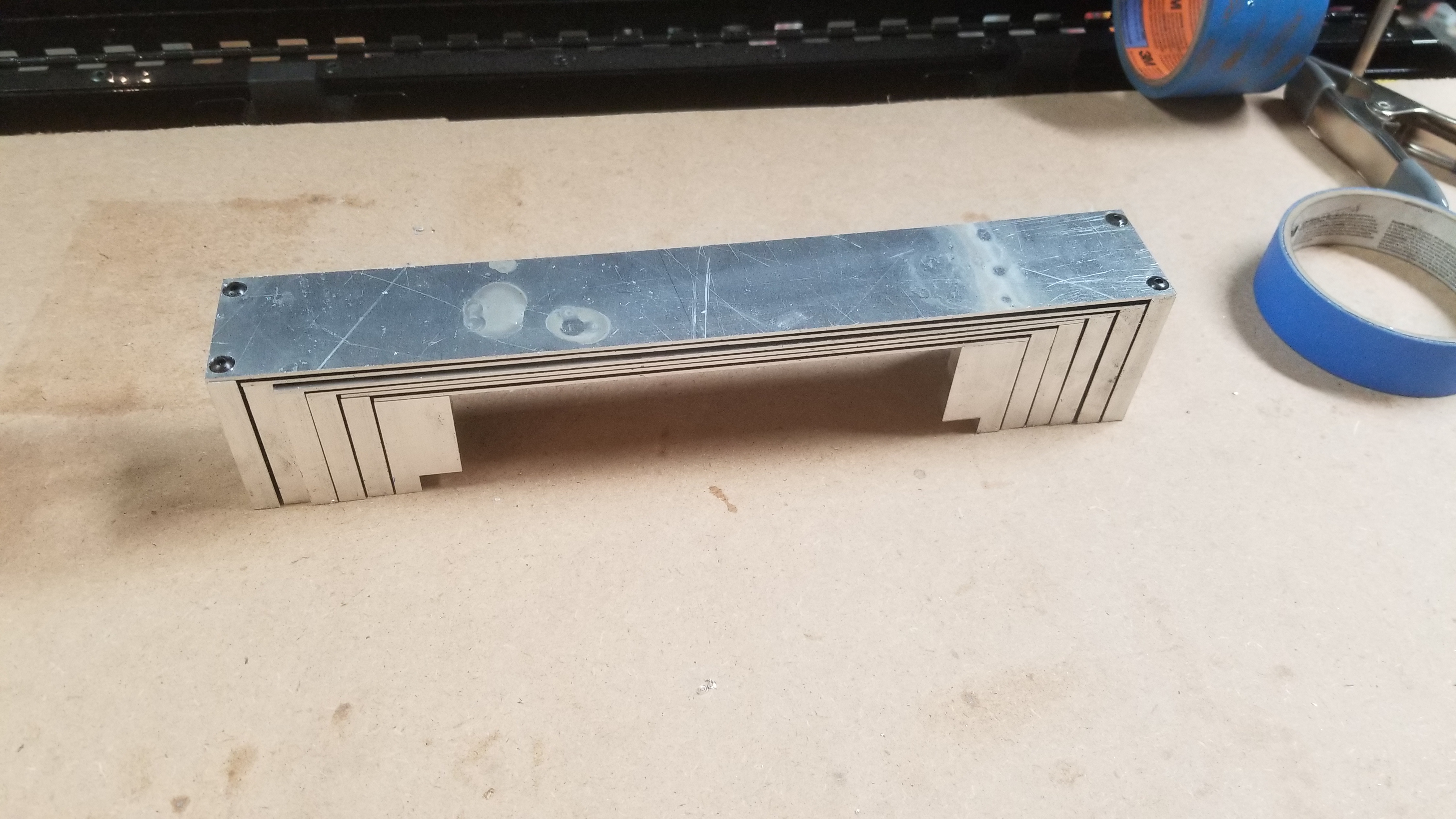

You can see the slight clearance between the segments here. Once I put the .025" adhesive rubber strips along the left side, that will be filled and should be kept uniform.

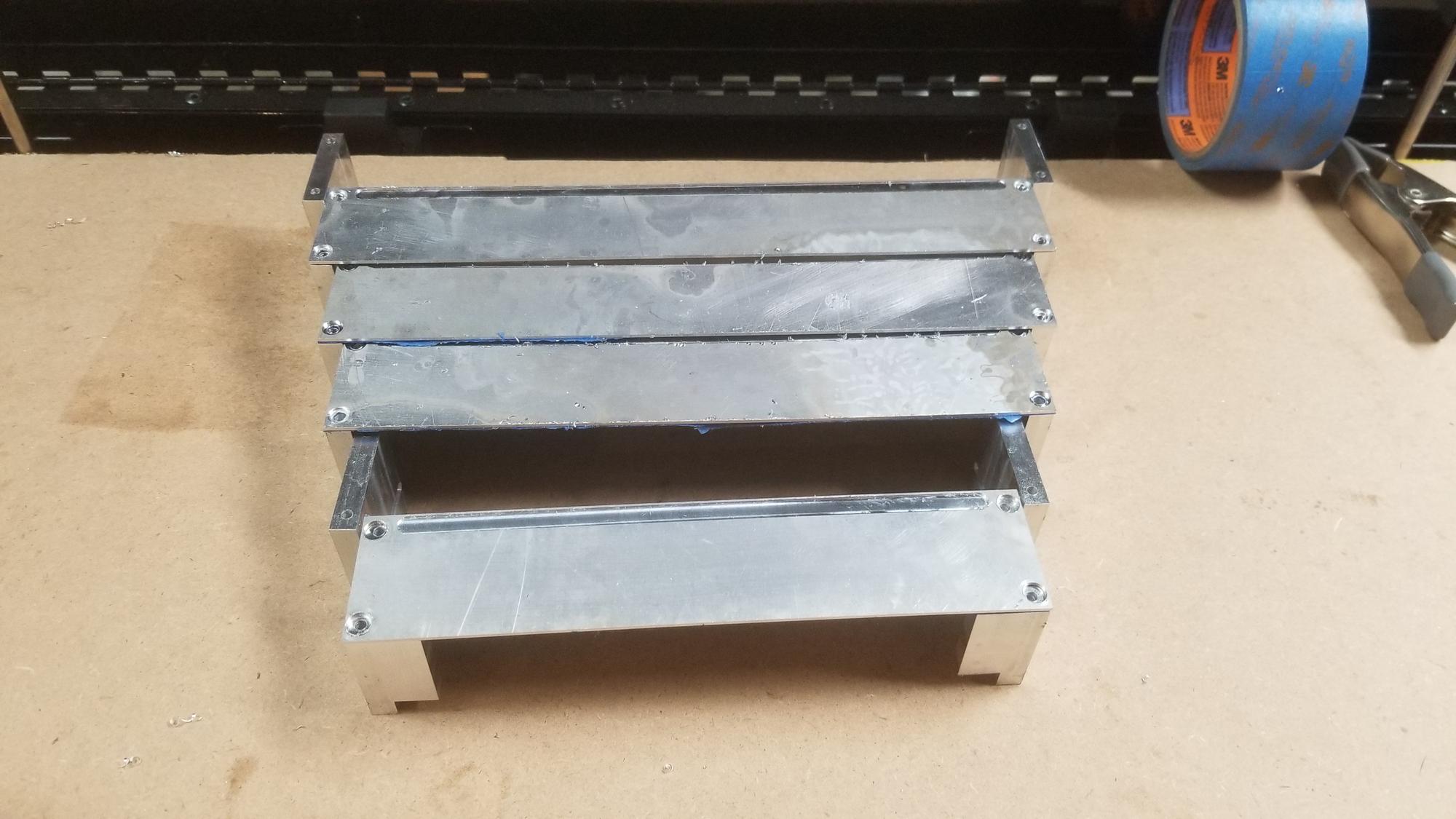

Here they are collapsed. You can see the sheets bowing slightly downward on a few of them. This creates the slightly larger gap between a few sheets. You might also notice the topmost ones have a slightly larger gap than the rest of the sheets. That would be because someone wasn't careful enough when he modeled it and made that gap too large...

I am thinking I will sand the sheets to a brushed finish, maybe around 800 grit sandpaper. I don't want to make them shiny and then have them look rough as soon as a chip scratches them, but I also think they will wear better with a surface that slides easier.

One step closer to getting this machine the way I want it! It will soon be time to wrestle with the new electronics set up. I am looking into building a new PC to control it. I want to get rid of the big ol computer that has to sit next to the machine. Hopefully something with slightly better performance that I can fit in a smaller package. I was thinking of putting the control PC in the same box as the electronics, but the fear of noise interfering is pushing me to give it its own box.