- Joined

- Aug 6, 2015

- Messages

- 3,934

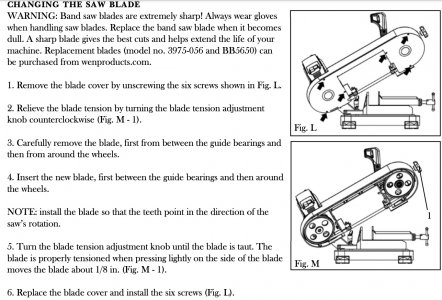

Remove six screws and the cover... loosen tension and replace. Seems pretty easy. I will time it when it gets here as the first thing I will do is to replace the blade that it comes with.I'd be interested to see how the blade changes are done on this saw. The 4x6" has an annoying blade change which takes me about 10 minutes, several screws to undo, and a few parts that have to be removed or at least moved out of the way. The larger HF/Jet/Grizzly 7x12 is a little better, but still kind of slow. The Kalamazoo on the other hand is very quick and easy, I can change a blade in about 2 minutes. I suspect part of the difference is safety related. The Kalamazoo is a pre-1970 model so the blade and moving parts are more exposed. It could be done, but you would have to be a special kind of idiot to get a body part wrapped up in the moving bits.

And based on your comment and a from a few other forum members, I went ahead and also ordered two more USA made bi-metal blades... one 14-18 and one 20-24... these are SuperCut brand as I could not find them from Starrett...

Last edited: