Got a chance to visit

@mmcmdl and bring home an arbor press stand, and some miscellaneous pieces of 80/20. The arbor stand is made of stainless and will be great for my use. I have enough 80/20 to make up a small table for another use. Was fun visiting Dave and his collection of stuff! I was most fortunate not to be driving a large vehicle, nor towing a trailer, otherwise I would have had to make a new addition to my house! He had some nice machines there. The ride back took me through a different way, that was more rural, which was a lot nicer than the ride on I-95. The last time I had been through that general area was around 1975. Was great to see it again.

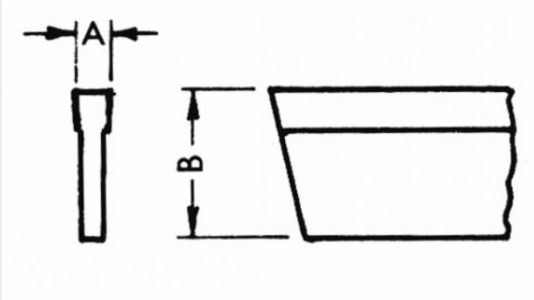

View attachment 412499

True to my word, I left room for my wife and her bags to get home. Won't have to strap her to the roof - she was worried, I get carried away sometimes

and

and