Hey Ulma,

I have enjoyed reading your articles on Henrietta, (good homely name for the old girl) Your workmanship is excellent, as is your work/conservation/historical and general love for this old machine If anyone was to ask me "did the man carry out an uneconomical repair?, Iwould have to concurr you bet", But you have the same ethos as me cost & time considerations are way down the scale, It all bo8ills down to the love of venerable old iron which made our nations great, your lathe is in the same genre as my big slotting machine, Old fashioned Yes, built at the beginning of the second world war , and was responsible for pulling us all out of a real mess! Both unsung heroes

Last autumn, I ventured down to the North of England to purchase a little Zyto lathe , It is a London build , first saw the light of day in its embryo form many years ago I think just after the first world war, My example which I obtained was one of the firms last designs late 1940-to mid fifties, I purchased it from a thoroughly nice & decent English gentleman , who could not have been more helpfull if he had tried, Like Henrietta it was in a poor state, very dirty, but after months of cleaning up came a little lathe with virtually zero wear, and minimum damage, only the bronze bearing shells wich I had to remake.

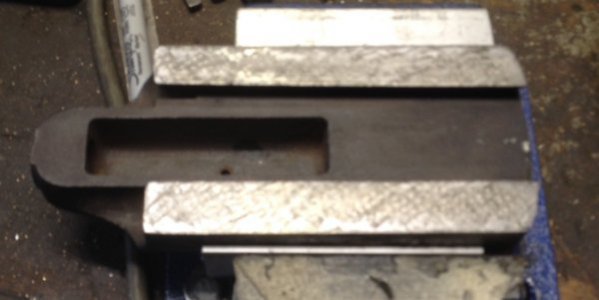

Unlike Henrietta which is a production lathe , my lathe is a small 3&1/4" centre height x 12" between centres screwcutting lathe, built for the home craftsman, She is a cone drive lathe from an overhead countershaft (Missing ) So I have now began making a suitable countershaft with fast & loose pulleys and matching cone , Like your lathe flat belt drive, I have been taken to task , by "experts" , for wasting precious time repairing a machine of an outdated pattern, when sitting across from it I have a really nice Myford , A make of lathe which superseded it as regards the general British home shop guy from the late fifties onwards, But it is little pattern of machine upon which was made superb model engines and other lovely things in its day. A nice homely thing from my early teenage years , Guess Ulma it all boils down to love of old iron.

Ulma, I most certainly am looking forward to your final report on your lathe ticking over. Keep up the good work.

)

)