-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1st,& 2nd knurl

- Thread starter Aukai

- Start date

- Joined

- Apr 28, 2014

- Messages

- 3,590

Or both. Plus 'Knurling Junkie'

Knurlophobic, or knurlaholic?

One may become the other, grasshopper.

Robert

- Joined

- May 4, 2015

- Messages

- 3,583

Everyone wants sharp pointed knurls. Much depends on material and technique. But all are formed not really cut. Lubricant use is almost a constant with pressure , charts for sizes n speeds . The rest is you if your toolings in good condition and usable. So go make diamonds n practise.

- Joined

- Mar 25, 2013

- Messages

- 4,615

Darkzero- I have a knurl question for you since you are the resident expert! I took my Accutrak knurls that are marked as 20 TPI and I rolled them out on paper to check the pattern. When I count the marks per inch of paper I get 18 TPI? Is there another way this is calculated? Perhaps they use the pitch diameter (which would be smaller) but that would make the TPI even lower?

Robert

Robert

- Joined

- Nov 27, 2012

- Messages

- 7,854

Thanks Robert but I'm certainly no expert!

Unfortunately I have no idea. I have never thought to check any of my wheels like that, I always trusted what was marked on the wheels or I have counted the teeth on a wheel (just for fun). Accu-Trak has a chart on their site that lists the number of teeth for a given wheel size (diameter) & pitch. May not help answer what you are wondering but helps if the markings ever become unreadable.

Maybe somewhere in their technical resource might have the answer? Oh looks like they updated their website.

Unfortunately I have no idea. I have never thought to check any of my wheels like that, I always trusted what was marked on the wheels or I have counted the teeth on a wheel (just for fun). Accu-Trak has a chart on their site that lists the number of teeth for a given wheel size (diameter) & pitch. May not help answer what you are wondering but helps if the markings ever become unreadable.

Maybe somewhere in their technical resource might have the answer? Oh looks like they updated their website.

- Joined

- Mar 25, 2013

- Messages

- 4,615

I am trying to figure out how the number of teeth per wheel would vary from a straight to a diagonal knurl of the same TPI??? I think there is some witchcraft afoot.

Robert

EDIT:

Check this page out.

R

Robert

EDIT:

Check this page out.

- Joined

- Nov 27, 2012

- Messages

- 7,854

Check out this page, it may have some answers for you.

TEETH per INCH or TPI. The TPI refers to the number of Teeth per (linear) Inch measured on the circumference of the work blank diameter. For straight knurl wheels the approximate TPI, may be measured on the outside diameter of the knurling for reference purposes. For diagonal knurl wheels, the

*TPI is measured perpendicular to the teeth or helix angle. The circular pitch measurement in inches, is derived from 1 inch divided by the number of Teeth per Inch with the exception of 14, 21, and 33 TPI.

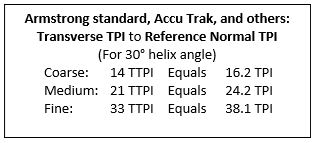

In the middle of the 20th century, some knurl manufacturers (Armstrong and Williams) sold only 3 different pitches of diagonal knurling wheels as standard: Coarse, Medium and Fine.

They measured the pitch of their tools by the “Transverse TPI” (TTPI) as shown below. 1/transverse circular pitch = TTPI.

The 3 pitches were:

So, for example, a 14 TTPI wheel is a slightly “finer” pitch, not coarser, than a 16 NTPI wheel, which has caused much confusion over the years. Except for these 3 TPI’s, Accu-Trak, and all other current knurl manufacturers, produce their diagonal and diamond knurling wheels to the “Normal TPI”. (TPI) = 1/normal circular pitch.

- Joined

- Apr 23, 2013

- Messages

- 1,004

Not needed in a home shop . But lots of machinist don’t know shops that do thread rolling can also roll knurls. I used to do a job out of 316ss 1 1/2 dia 1000 pcs at a time and never lost any parts due to bad knurls. But I had to finish the Id after knurling because part bore would move from knurling .