-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2015 POTD Thread Archive

- Thread starter jumps4

- Start date

- Joined

- Dec 27, 2014

- Messages

- 4,059

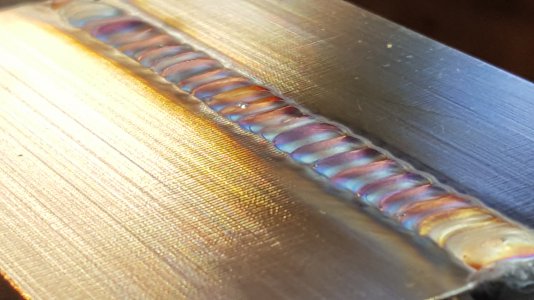

If I didn't know it was skill and craft, I'd want to call it art.

- Joined

- Sep 2, 2013

- Messages

- 5,109

Made a motorcycle laser alignment tool:

That's pretty cool. What vintage is your Venture? Mike

- Joined

- Jan 25, 2015

- Messages

- 2,558

1983.

It's getting some major work done.

I bought it this year as an unmolested bike with 32,000 kms on it. Spent its life mostly in a heated garage:

I resisted the urge to do anything other than ride it for about 6 months.

I'm in the process of adding a 2002 royal star transmission gear set, vmax rear differential. VMax heads and vboost manifolds.

It's getting coil over plugs and digital ignition.

I'm ditching the old bias ply tires and putting 17" radial tire rims on it. Thats the reason for the green rear rim off a zx7r (modified to hold the spline drive for the shaft) and a 2006 r6 front rim. The wheel swap is the main reason I built the laser alignment jig (needs swingarm work to fit the 180/70r17 rear tire/rim).

Cartridge emulators for the front forks and I'm still working on what to do with the rear. I was working on a zg1400 shock, but I don't think that is going to work out (too long).

R6 monoblock calipers are also going on.

It's getting the later style side paniers in the photo, since they have more capacity than the 83-85 ones.

I'm also chucking on a set of r1 mufflers, mostly because they look kinda cool sticking out under the bags:

I'm thinking of making it sort of a "bagger" for around town use:

(That's just an image I grabbed off the net and photoshopped )

Sort of a "honda f6b" concept. Low enough sheild to get a good blast of wind in the face around town (gets pretty warm behind the tall shield at low speeds) and put the top trunk and tall windshield back on for long distance rides. Bagger like the above pic is easy to do. I'll just build a second seat to bolt on and off with the small rear duck tail on it.

Lots of work done, lots of work to go....

It's getting some major work done.

I bought it this year as an unmolested bike with 32,000 kms on it. Spent its life mostly in a heated garage:

I resisted the urge to do anything other than ride it for about 6 months.

I'm in the process of adding a 2002 royal star transmission gear set, vmax rear differential. VMax heads and vboost manifolds.

It's getting coil over plugs and digital ignition.

I'm ditching the old bias ply tires and putting 17" radial tire rims on it. Thats the reason for the green rear rim off a zx7r (modified to hold the spline drive for the shaft) and a 2006 r6 front rim. The wheel swap is the main reason I built the laser alignment jig (needs swingarm work to fit the 180/70r17 rear tire/rim).

Cartridge emulators for the front forks and I'm still working on what to do with the rear. I was working on a zg1400 shock, but I don't think that is going to work out (too long).

R6 monoblock calipers are also going on.

It's getting the later style side paniers in the photo, since they have more capacity than the 83-85 ones.

I'm also chucking on a set of r1 mufflers, mostly because they look kinda cool sticking out under the bags:

I'm thinking of making it sort of a "bagger" for around town use:

(That's just an image I grabbed off the net and photoshopped )

Sort of a "honda f6b" concept. Low enough sheild to get a good blast of wind in the face around town (gets pretty warm behind the tall shield at low speeds) and put the top trunk and tall windshield back on for long distance rides. Bagger like the above pic is easy to do. I'll just build a second seat to bolt on and off with the small rear duck tail on it.

Lots of work done, lots of work to go....

Last edited:

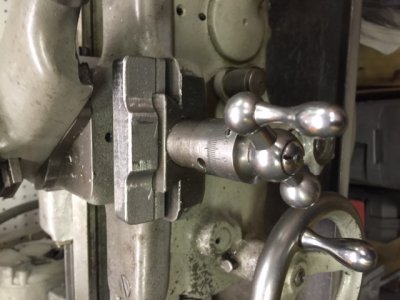

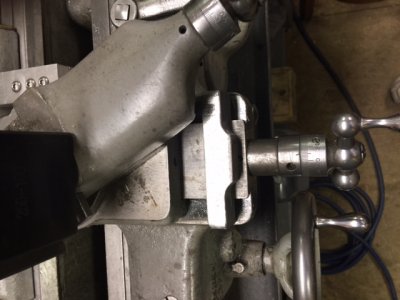

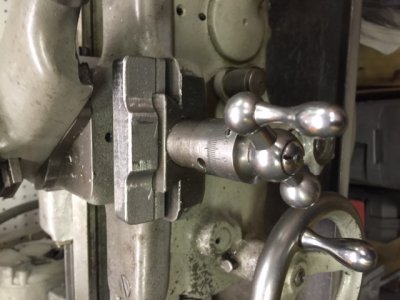

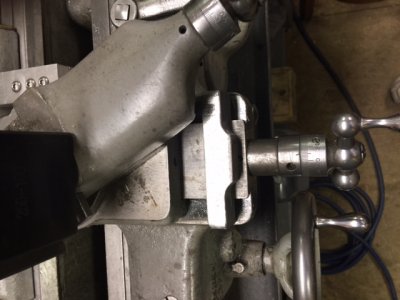

One of the projects I had planned for some time was to make a copy of the threading stop for the South Bend lathe. I found a chunk of cast iron I had saved from a broken vise and decided to make this the first project completed in the new year. I patterned the piece after the original by South Bend. The originals of this is going for $50 to $100 on the Bay but this cost me nothing.

The attached images are the piece after sawing the chunk to size, then milling the final shape. The last step will be to drill the bolt hole and the hole in the side for the set screw and shoe to clamp it in place. This is an easy project that took about an hour on the mill and will certainly make threading much easier.

The above two images are the chunk of cast iron after milling. It is 3.25"long, .900" high.

The last two images are the piece set on the lathe. To finish this little project , I will drill the bolt hole the accepts the bolt that screws into the cross slide and drill the hole for the set screw and shoe that clamps the stop on the lathe.

The cast iron machined very nicely.

The attached images are the piece after sawing the chunk to size, then milling the final shape. The last step will be to drill the bolt hole and the hole in the side for the set screw and shoe to clamp it in place. This is an easy project that took about an hour on the mill and will certainly make threading much easier.

The above two images are the chunk of cast iron after milling. It is 3.25"long, .900" high.

The last two images are the piece set on the lathe. To finish this little project , I will drill the bolt hole the accepts the bolt that screws into the cross slide and drill the hole for the set screw and shoe that clamps the stop on the lathe.

The cast iron machined very nicely.

I have been getting familiar with my new G0704 by machining some custom hardware parts for a guitar I am working on. Shown below are tuning blocks, saddle brackets, and a string retainer block, all out of 6061. I am thinking I will get them buffed up nicely and then maybe a satin clear powder coat so that the finish doesn't get messed up. I could anodize, but home anodizing doesn't harden the surface too much, or so I have read. It's been good basic exercise. I plan to CNC the X and Y axes soon, but learning how it handles manually is nice.

- Joined

- Aug 22, 2012

- Messages

- 4,122

heavy plastic sewer pipe is a good material, one standard end cap and a screwed end cap with "O" ring seal and the tub is done.thanks Charles, a rock tumbler is definitely on the list but it'll have to wait until after our next and hopefully final move, fingers crossed next year. funnily enough my grandad had one years ago

The end caps are then also the flanges that sit on the rollers.

Mind you if you have the bucks then a vibratory tumbler is way faster.