- Joined

- Mar 12, 2014

- Messages

- 1,531

I am embarassed to say this but I have had a 3-jaw chuck and backing plate blank sitting on my bench for the past 9+ months now and no time to work on it. I have a 8" Vertex Rotary Table that I acquired about 8 or so years ago. I haven't used it much due to what a pain it was to use the mill feature on my previous 3-in-1 machine. However, I decided to finally set it up with a 3-jaw chuck and start using the rotary table a bit more. Last summer I scored an inexpensive 3-jaw from ebay and a blank backing plate to mount the chuck onto my rotary table. It has been sitting on my work bench ever since because I have not had time to machine the adapter plate.

Well, I have a set of handlebar mounts to machine for a customer's bike and I could really use that 3-jaw to cut the radius on the mill. I figured it was time to get the adapter place machined so I could use it for this project and it would be completed and readily available whenever I need it in the future.

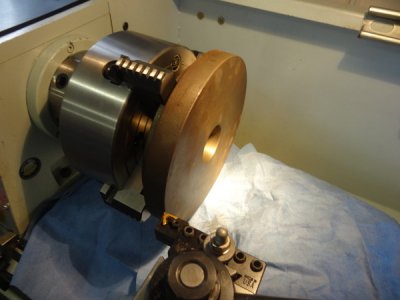

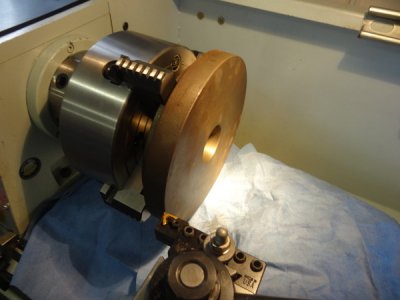

I set up the adapter plate in the 4-jaw and dialed it in. I also covered the bed, carriage and as much of the lathe as possible as I hate machining cast iron.

I next faced the backing plate and cut the OD to size. It originally measure 8.3" and I needed to take it down to 8" exactly to match the rotary table diameter.

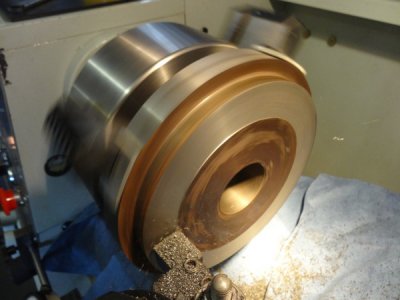

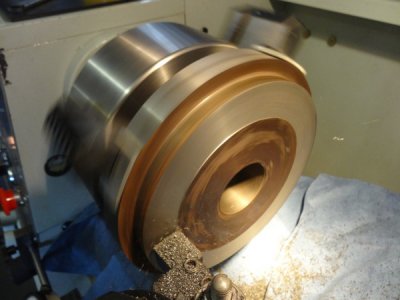

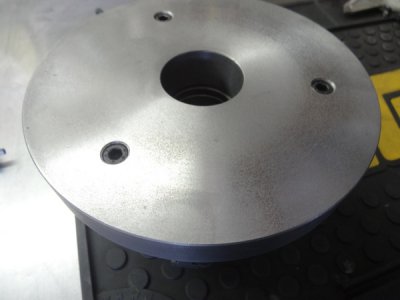

Once I got it trued and turned down, I flipped it around in the 4-jaw to machine the step to match the back side of the 3-jaw chuck.

Here is the little 6" 3-jaw that will be used on my 8" rotary table.

Hopefully tonight I can complete the step and then move over to the mill and drill the bolt holes for mounting the chuck to the backing plate and the backing plate to the RT.

Mike.

Well, I have a set of handlebar mounts to machine for a customer's bike and I could really use that 3-jaw to cut the radius on the mill. I figured it was time to get the adapter place machined so I could use it for this project and it would be completed and readily available whenever I need it in the future.

I set up the adapter plate in the 4-jaw and dialed it in. I also covered the bed, carriage and as much of the lathe as possible as I hate machining cast iron.

I next faced the backing plate and cut the OD to size. It originally measure 8.3" and I needed to take it down to 8" exactly to match the rotary table diameter.

Once I got it trued and turned down, I flipped it around in the 4-jaw to machine the step to match the back side of the 3-jaw chuck.

Here is the little 6" 3-jaw that will be used on my 8" rotary table.

Hopefully tonight I can complete the step and then move over to the mill and drill the bolt holes for mounting the chuck to the backing plate and the backing plate to the RT.

Mike.

.

.