Going Around in Circles.

Some time ago, I mounted a laser pointer in my boring head to make an adjustable diameter circle generator for locating the center of holes or bosses. It worked well but the overall length was not convenient. With an improvement in mind, I purchased a red laser module and began designing.

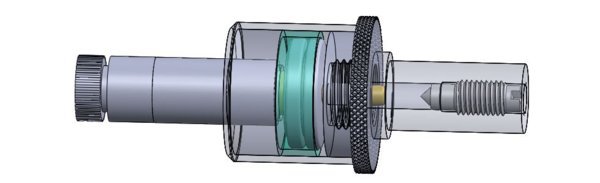

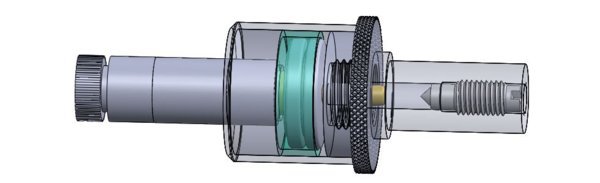

The laser consists of the laser module, a battery housing, and a 1/2" arbor to fit my boring head. The final design used two CR2032 lithium cells for the 6 volt supply. The laser module was modified by connecting the negative lead to a contact button with the positive connection through the module housing. the batteries were stacked with the negative face of the bottom battery in contact with the button and a grounded spring loaded button in contact with the positive face of the top battery. To turn the laser off, the arbor is unscrewed a half turn.

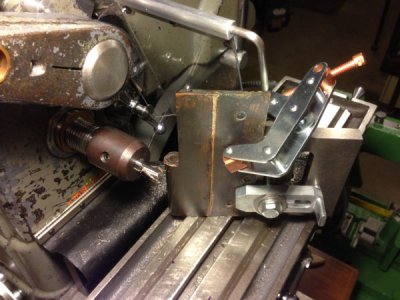

The machining was done on my G0602 lathe, using my 5c collet chuck. The housing was made in three pieces, a base, the housing tube and a cap. In order to be able to replace thwe batteries, the cap was threaded. The tubing wall was only .050"" so a fine thread had to be used. I elected to use a 40 tpi thread with a major diameter of .925". I made the cap first so I could use it as a gage to check the internal thread. This was my first internal thread in more than twenty years and I had never single pointed a thread that fine before. The result was better than expected with no noticeable play in the thread but smooth movement.

Two insulators were turned from Delrin to prevent the batteries from shorting to the case. A third insulator made from Teflon tape was used on the cap. The spring loaded contact has adjustable pressure due to a brass adjustment screw. As a final touch, the rim of the cap was knurled to improve grip.

The laser was mounted in my boring head and used to locate a hole in a bushing. The diameter of the laser sweep was set at just slightly larger the hole in the bushing. I found that I was able to center the laser to within a thousandth of the true center.

While my location tool of choice is my trusty edge finder, I can think of instances where the laser will be a useful tool.