- Joined

- May 24, 2012

- Messages

- 395

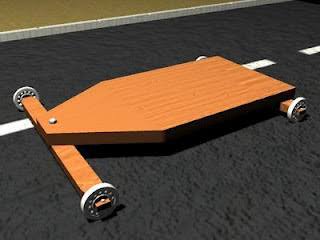

Please add a link or pics of the type of car you're talking about. A Google search showed only gravity powered vehicles with MUCH larger diameter tire/wheel size.

At this moment I only have the wheels. It will be gravity powered small car for kids around 5 years. Cars like image below was very common when I was a kid. My plan is keep the simple concept but with a steering wheel on a square tube chassis keeping things as funny as possible.