Sent from my iPhone using Tapatalk

![IMG_20180427_153719[1].jpg IMG_20180427_153719[1].jpg](https://www.hobby-machinist.com/data/attachments/223/223470-258ede39f91d3790b16cedf7faf6755c.jpg)

![IMG_20180427_153626[1].jpg IMG_20180427_153626[1].jpg](https://www.hobby-machinist.com/data/attachments/223/223468-707651ffe275f5e2caf3f9d732b5dce0.jpg)

![IMG_20180427_153632_-_Copy[1].jpg IMG_20180427_153632_-_Copy[1].jpg](https://www.hobby-machinist.com/data/attachments/223/223469-d38086c8a2807ae15d3d8791456a42cb.jpg)

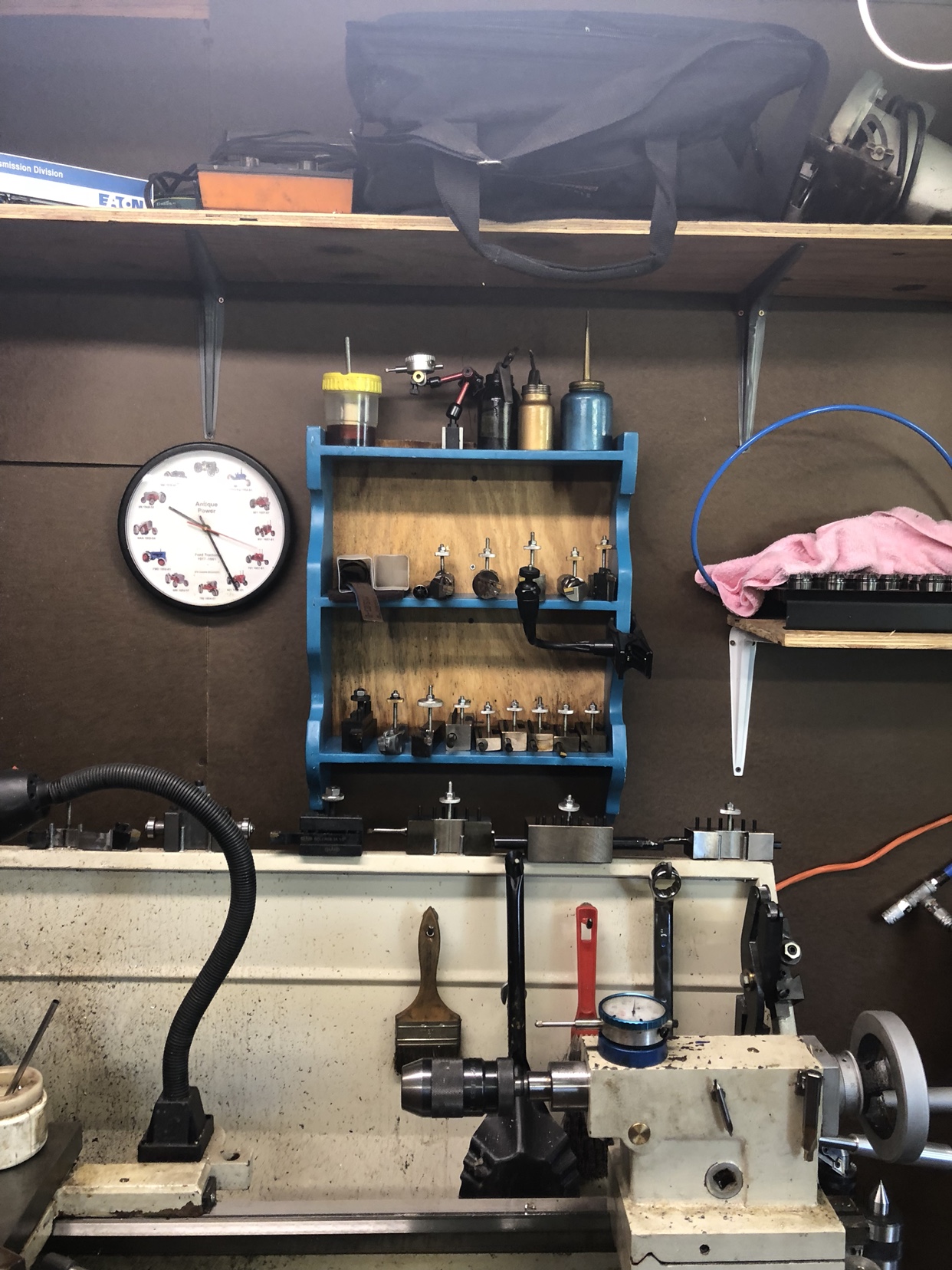

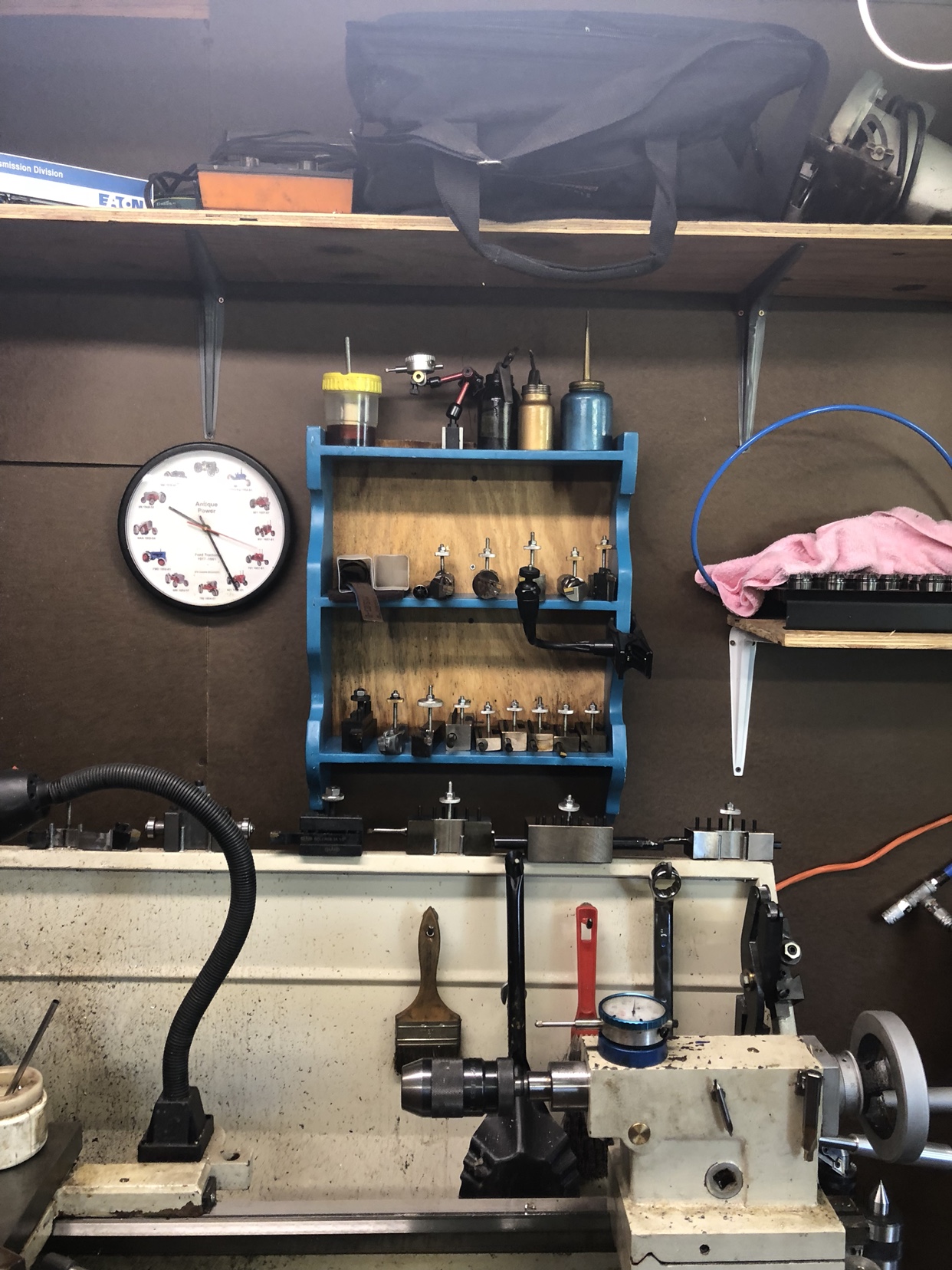

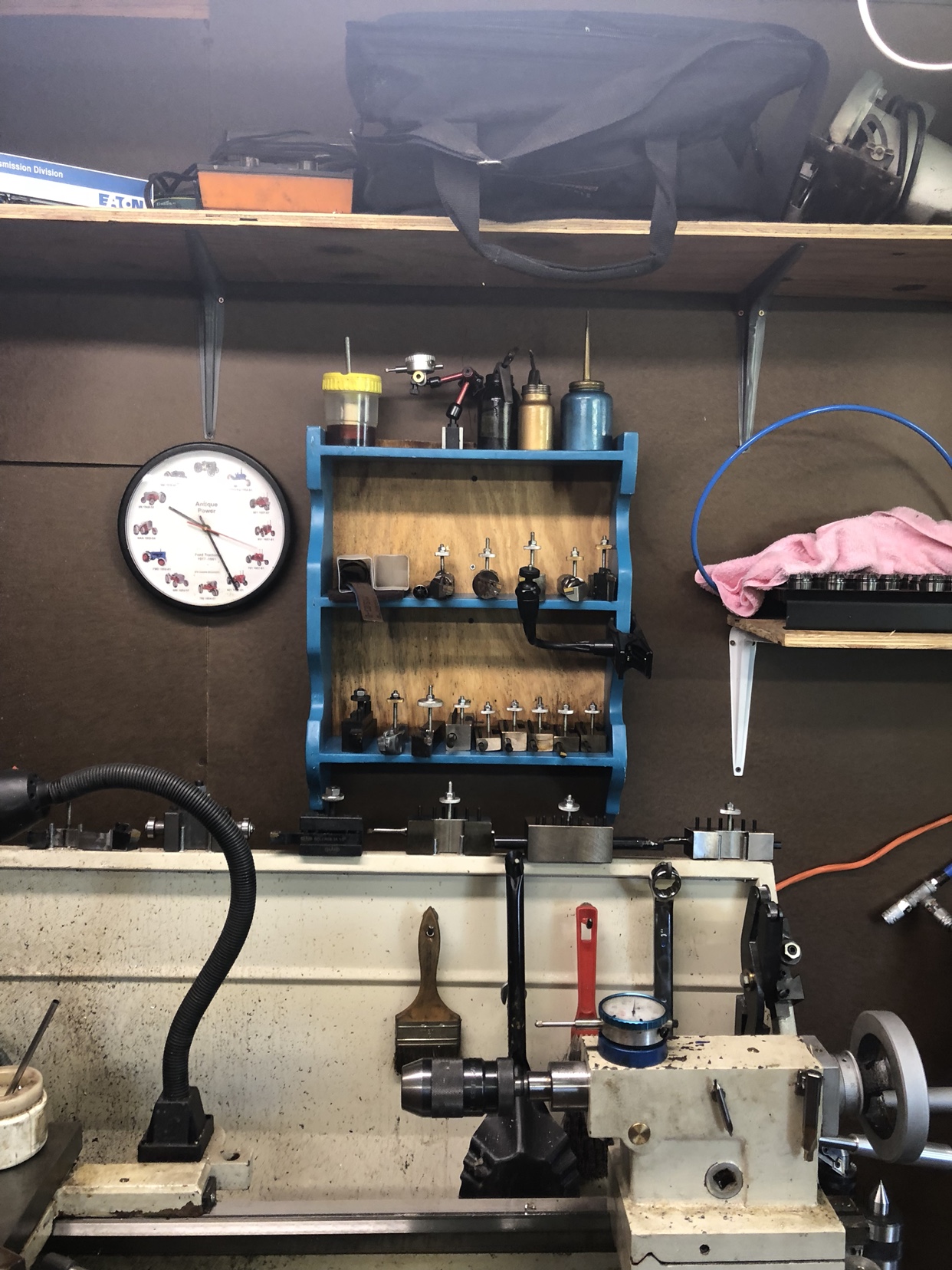

This is the best I could come-up with for a quick project today. I got tired of using a 14" adjustable wrench on a ER32 chuck and made this special Terminator T-1000 unit.

The jaws are made of 4340. The handle is some 3/8" 316 SS rod left over from another project. Everything was tig welded then, the 4340 jaws were heated red with a torch, quenched, then tempered a little. The ergonomics feel good and it's very sturdy. I don't think any amount of human force could splay the jaws.

View attachment 266233View attachment 266231View attachment 266232

I'm going to make one for the ER40 chuck too.

Ray

![IMG_20180427_184457[1].jpg IMG_20180427_184457[1].jpg](https://www.hobby-machinist.com/data/attachments/223/223483-382fed40279f2645b244bdc280f171d1.jpg)

![IMG_20180427_184527[1].jpg IMG_20180427_184527[1].jpg](https://www.hobby-machinist.com/data/attachments/223/223484-912f2373ef67451f0565c7f545a5afcd.jpg)

![IMG_20180427_191002[1].jpg IMG_20180427_191002[1].jpg](https://www.hobby-machinist.com/data/attachments/223/223485-b022ac1e3fa7ec9880c797c48b42b756.jpg)

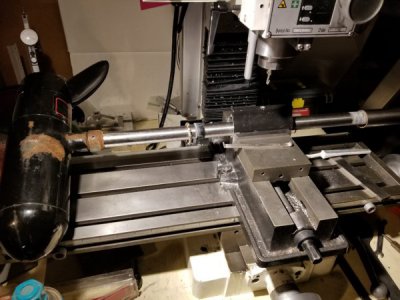

This is my all-time, favorite face cutter. 3/4" Weldon shank. Three cutters, 90 degree, 1.5" diameter.

Just caught this in time. Using my Makita thickness planer today and noticed the arcing smell. Hum, pulled the brushes and found the wire in one JUST poking through. Left a tiny ring on the commutator.

View attachment 266245

Couldn't believe I had a spare set.

Greg

![IMG_20180428_091906[1].jpg IMG_20180428_091906[1].jpg](https://www.hobby-machinist.com/data/attachments/223/223542-5d2bea0fc09387c03162ff0db2c1eaa1.jpg)

![IMG_20180428_095224[1].jpg IMG_20180428_095224[1].jpg](https://www.hobby-machinist.com/data/attachments/223/223543-1911e0b331da9447c915948b64eb97be.jpg)

![IMG_20180428_104738[1].jpg IMG_20180428_104738[1].jpg](https://www.hobby-machinist.com/data/attachments/223/223544-e63883e3cbc42ab77f21259eb83ca61d.jpg)

![IMG_20180428_123111[1].jpg IMG_20180428_123111[1].jpg](https://www.hobby-machinist.com/data/attachments/223/223545-930390824594a71a97f17e6a509baf7d.jpg)