- Joined

- Nov 16, 2012

- Messages

- 5,596

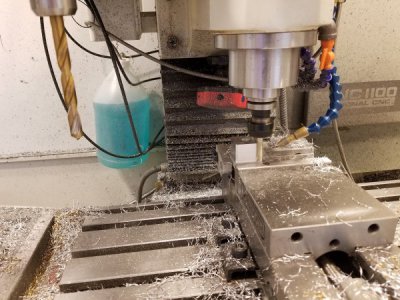

I'm working on another project for a mill-head power lift https://www.hobby-machinist.com/threads/power-z-conversion-for-pm45.69552/ and need to cut some gears. The gear cutters I'm using are 22mm ID and my existing gear cutter arbor is 1" so.... time to make a 22mm gear cutter arbor.

This is made from 1117 which I really don't care for. Its strong yet cuts like butter but always gives that dull matte finish. Anyhow, here are a few action shots.

Oh BTW, this one is reversible and can be used with 1" or 22mm gear cutters.

1" on one end. 22mm on the other. Just need to make different spacers.

Key slot. Gotta have a key for gear cutting or that cap won't stand a chance.

Here's a poor-mans "broach" for the keyway in the spacer. I have a broaching kit but really didn't feel like messing with it. This is quick, dirty and perfectly effective for the intended purpose.

All the pieces for 22mm setup. The clearance between the shaft and ID of the cutter is well under a thou. You don't want a sloppy fit or it will give uneven wear on the cutting teeth.

Ready to rock & roll... Different spacers can be made as needed to position the cutter further down on the shaft.

Fun little project.... These things are expensive (around $50) when you buy them. This cost Zip in materials.

Ray

This is made from 1117 which I really don't care for. Its strong yet cuts like butter but always gives that dull matte finish. Anyhow, here are a few action shots.

Oh BTW, this one is reversible and can be used with 1" or 22mm gear cutters.

1" on one end. 22mm on the other. Just need to make different spacers.

Key slot. Gotta have a key for gear cutting or that cap won't stand a chance.

Here's a poor-mans "broach" for the keyway in the spacer. I have a broaching kit but really didn't feel like messing with it. This is quick, dirty and perfectly effective for the intended purpose.

All the pieces for 22mm setup. The clearance between the shaft and ID of the cutter is well under a thou. You don't want a sloppy fit or it will give uneven wear on the cutting teeth.

Ready to rock & roll... Different spacers can be made as needed to position the cutter further down on the shaft.

Fun little project.... These things are expensive (around $50) when you buy them. This cost Zip in materials.

Ray