- Joined

- Mar 20, 2014

- Messages

- 418

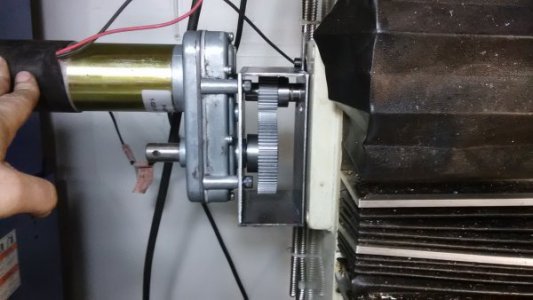

I posted this yesterday, but it seems have gone AWOL during the server move - so here it is again.

I machined a pin / spring retainer for my kit car brake pedal return spring. Where I had the spring previously (pulling back from the clevis pin where the booster arm is attached to the pedal) wasn’t returning the pedal to the fully up position. Which meant that the brakes where dragging, unless you lifted the pedal up with your toe...

I turned this from an M12 bolt. It’s been taken down to 8mm diameter for most of the length, with a groove cut so the spring end sits in it. The bolt head has been shaved down, leaving an 8mm register which is itself drilled and threaded to accept an M6 bolt.

It’s attached to the pedal via an 8mm hole cross drilled through the pedal arm. The register locates it, and the M6 bolt with a washer holds it in place. The bolt has been blue loctited in place.

Makes so much difference. Although I will miss ping ping ping of my rear brakes cooling down now.

There’s lots more picks of Vikki over on her build blog: http://www.greatoldone.co.uk/

I machined a pin / spring retainer for my kit car brake pedal return spring. Where I had the spring previously (pulling back from the clevis pin where the booster arm is attached to the pedal) wasn’t returning the pedal to the fully up position. Which meant that the brakes where dragging, unless you lifted the pedal up with your toe...

I turned this from an M12 bolt. It’s been taken down to 8mm diameter for most of the length, with a groove cut so the spring end sits in it. The bolt head has been shaved down, leaving an 8mm register which is itself drilled and threaded to accept an M6 bolt.

It’s attached to the pedal via an 8mm hole cross drilled through the pedal arm. The register locates it, and the M6 bolt with a washer holds it in place. The bolt has been blue loctited in place.

Makes so much difference. Although I will miss ping ping ping of my rear brakes cooling down now.

There’s lots more picks of Vikki over on her build blog: http://www.greatoldone.co.uk/