-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2021 POTD Thread Archive

- Thread starter Gaffer

- Start date

- Joined

- Oct 28, 2020

- Messages

- 528

Me alsoBeautiful work! At first glance, the pictures made it look like it was bicycle powered.

- Joined

- Aug 6, 2015

- Messages

- 3,910

Beautiful work! At first glance, the pictures made it look like it was bicycle powered.

Me also

I tried to get the wife to pedal while I did the sewing and she would not go for it...

- Joined

- Aug 6, 2015

- Messages

- 3,910

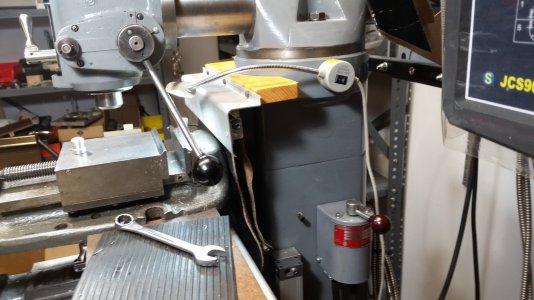

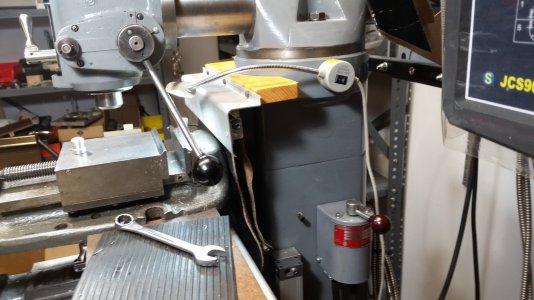

Started making the vise handles for the Wilton vise... first attempt did not go that well...

Photo is just testing the threads... at this point I decided to make them again... had only done that one...

I have a thread gauge... Did I use it to measure the threads I needed to make? Noooooooooo... I used 1/2"-20 tap instead of 1/2"-13 tap... Not such a big deal as I was able to tap it with the 1/2"-13 and it worked... but then I turned the part too much... I should have left it at .80"

I used 1/2"-20 tap instead of 1/2"-13 tap... Not such a big deal as I was able to tap it with the 1/2"-13 and it worked... but then I turned the part too much... I should have left it at .80"

So doing it again...

I have several inexpensive tap wrenches that I never use... just too cheap to be any good. But the handles will be perfect for this project.

Took two nuts, turned down to make the ends. Will cut some of the threads and then smash the remaining threads to make sure it does not come off. I will also take out most of the knurling from the handles. Will only leave the same size as the width of the nut on the other end... Hummm, as I write this, thinking that maybe it is best to make another set of those nut, thread the other end and do the same... so both sides look the same...

That is all I have been able to sneak out to do... long list of honey-do's that I have been busy with today...

And for those from the USA, a quick message from me to all the veterans that frequent this thread- Thank you very much for your service and defending our freedom. Without you I may not be able to enjoy this hobby I cherish. Happy Veterans Day !!!

Photo is just testing the threads... at this point I decided to make them again... had only done that one...

I have a thread gauge... Did I use it to measure the threads I needed to make? Noooooooooo...

So doing it again...

I have several inexpensive tap wrenches that I never use... just too cheap to be any good. But the handles will be perfect for this project.

Took two nuts, turned down to make the ends. Will cut some of the threads and then smash the remaining threads to make sure it does not come off. I will also take out most of the knurling from the handles. Will only leave the same size as the width of the nut on the other end... Hummm, as I write this, thinking that maybe it is best to make another set of those nut, thread the other end and do the same... so both sides look the same...

That is all I have been able to sneak out to do... long list of honey-do's that I have been busy with today...

And for those from the USA, a quick message from me to all the veterans that frequent this thread- Thank you very much for your service and defending our freedom. Without you I may not be able to enjoy this hobby I cherish. Happy Veterans Day !!!

Last edited:

- Joined

- Nov 25, 2015

- Messages

- 8,408

I made a handle for my Parker vise.

I did it the old fashioned way after watching Tom Lipton on youtube.

I just searched for one of them. I think this is the one I watched, it may have been another as he also fixed up a wilton.

But this has the process. I think you'll find it handy to know even if you decide you don't want to do it.

I did it the old fashioned way after watching Tom Lipton on youtube.

I just searched for one of them. I think this is the one I watched, it may have been another as he also fixed up a wilton.

But this has the process. I think you'll find it handy to know even if you decide you don't want to do it.

- Joined

- Aug 6, 2015

- Messages

- 3,910

That looks like a better approach. Thank you!I made a handle for my Parker vise.

I did it the old fashioned way after watching Tom Lipton on youtube.

I just searched for one of them. I think this is the one I watched, it may have been another as he also fixed up a wilton.

But this has the process. I think you'll find it handy to know even if you decide you don't want to do it.

- Joined

- Jul 14, 2017

- Messages

- 2,451

Today was judgement day for the W210 white elephant No:3. To say is rough is an understatement, its rusty leaky and very broken. Looking past the rust there is a decent car with good specs. In the past it definitely was a german taxi. That said those cars have very fuel efficient engine and the registration and insurance is very cheap. With how fuel prices are claiming that is a good thing. First thing i checked was the oil and it was 2,5 l low which i added, drove it 1st and 2gears are very hard to shift until i pump up the clutch, it's not adjusted right. Taking the beauty covers the engine is cover in oil and the oil dripping is getting worse and is starting to smoke out of the exhaust. To find the source i power washed the engine, you can see in the pictures that is steam not smoke, and then i could see the fuel injectors are dry and the oil is coming from the outlet of the turbocharger. Took off the pipe to and from the intercooler with the pipes off the engine stopped smoking from the exhaust it was sucking in engine oil thru the intercooler. The most immediately it needs a turbocharger and a radiator with those changed i can continue with my diagnosis. Also being a merc it has its own special 38 pin diagnostic port that i had to order so i can see what i need to do to turn off the christmas tree light on the dash. Good things it has a new battery, one new headlight, new hood emblem, and with everything broken it's still achieving 40 mpg city.

- Joined

- Sep 2, 2013

- Messages

- 5,138

Finally got around to soldering up the radiator lower hose outlet on the backhoe. Came out well. The actual joint is just above the heavier solder joint at the tank level. Just ran some solder in there to help reinforce it. The idler pulley for the water pump belt sounded a little crunchy, so I pulled it apart, cut a slot in the mounting plate to access the Allen head screws that hold the two piece pulley together, popped out the seal, and cleaned, and repacked it. It was pretty dry, but no play. Sounds nice and smooth now. The pulley wasn't running true, so a few well placed whacks with a big brass hammer convinced it to straighten up it's act. Filled her up with 50/50, and fired her up. Everything sounds good except the turbo is sounding a little tired, but that was on the list anyway, and will get a rebuild kit on order. Will put the nose piece, hood, and other stuff back on tonight, so will be ready for that first big snow. Cheers, Mike

Last edited:

- Joined

- Nov 25, 2015

- Messages

- 8,408

what I made was garbage. I'll tell ya, I think I am losing it. After being done with this and seeing that it won't work, I came to the realization that I had been down this road before and came to the same conclusion.. But I forgot... I also forgot where I put all those little baby jars that I had on one of my benches. I put them away, and needed to mix up some shellac, and could not find one.. I must have early onset alzheimer's.. I feel so stupid.

Here's the failure.. I'm not going to say what's wrong. see if you can guess.

Here's the failure.. I'm not going to say what's wrong. see if you can guess.