- Joined

- Aug 6, 2015

- Messages

- 3,886

Face mill should be fine. Start out easy, and see what it likes as far as DOC and feed. If you go with the end mill route, 2 flute would work best for this job. Mike

I think cutting the top of the track is a poor idea. Presumably, that area is work hardened, from tough service, so will hold up to hammering well and be difficult to cut with light equipment. If you want/need a flat surface to beat on, two options. Make a cradle to hold the track inverted or get a piece of plate stock.

I’ve heard the same thing about track being very tough and also that you’d have a better anvil by turning the track on end so that there is more mass under the hammer.

I am doing this to avoid using the anvil on the vise... and because it just looks so cool to have a piece of railroad track on the bench

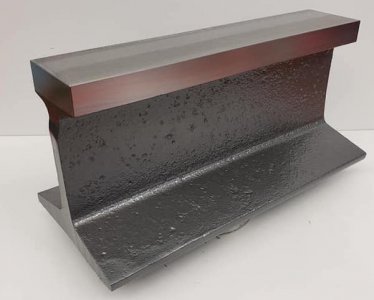

This is what I am going for:

I do not think that I want to make a jig to place it upside down...

Son: "What is that?"

Me: "Well Son, that is a piece of an old railroad track that I turned into an anvil"

Son: "But Dad, you destroyed a piece of American history to just bang it with a hammer?"

Me: "Shut up!"