- Joined

- Nov 25, 2015

- Messages

- 8,397

Ok, got a late start again, had to go out with the wife... get my meds so I am not crazy  ... not working...

... not working...

get some food, Oil for the vehicles.. I know you don't care...

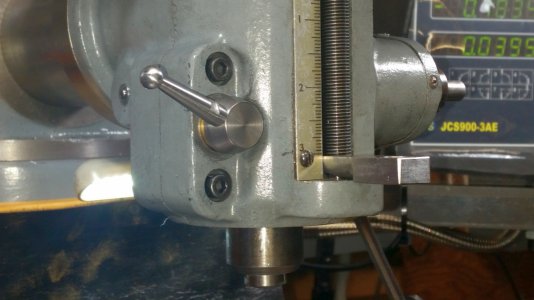

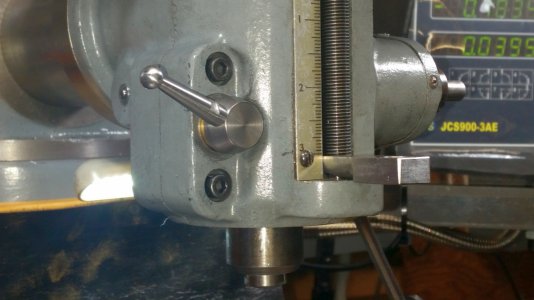

So wanted to finish off the quill lock.. man am I loving this. What a change, so much less annoying, frustrating, effort.

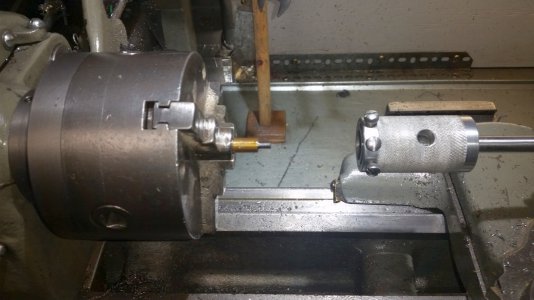

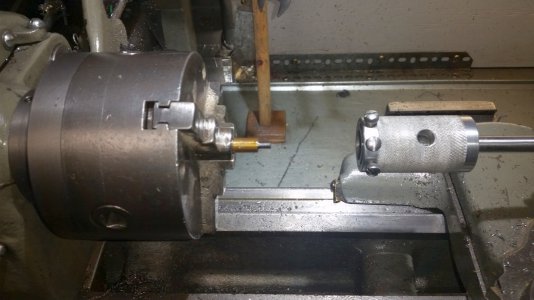

First made a mandrel to hold the handle. Just a small female threaded rod.

Then took the handle and put threads on it for holding in the mandrel.

Mounted.

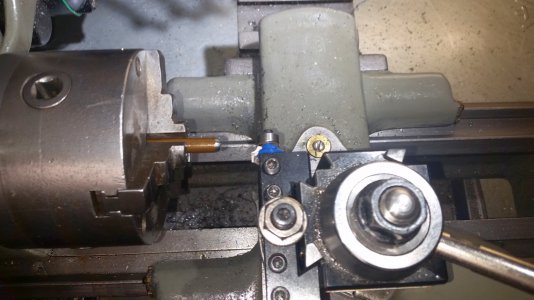

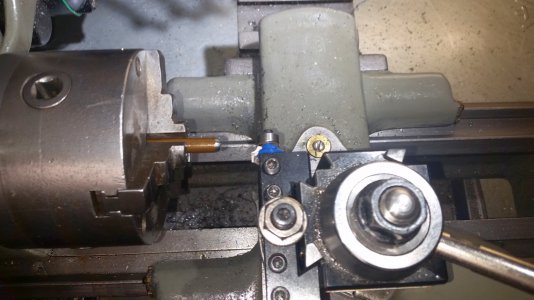

Couldn't find all the parts for my ball turner (my boring attachment) so I took out a router bit, for the first side.

I used the form tool at the bottom to do the rest of the ball

it required a few different cuts from different directions.

After shaping the handle, I brought it over to the mill, mounted it in a square block and

put some flats for tightening.

get some food, Oil for the vehicles.. I know you don't care...

So wanted to finish off the quill lock.. man am I loving this. What a change, so much less annoying, frustrating, effort.

First made a mandrel to hold the handle. Just a small female threaded rod.

Then took the handle and put threads on it for holding in the mandrel.

Mounted.

Couldn't find all the parts for my ball turner (my boring attachment) so I took out a router bit, for the first side.

I used the form tool at the bottom to do the rest of the ball

it required a few different cuts from different directions.

After shaping the handle, I brought it over to the mill, mounted it in a square block and

put some flats for tightening.