- Joined

- Mar 26, 2018

- Messages

- 8,407

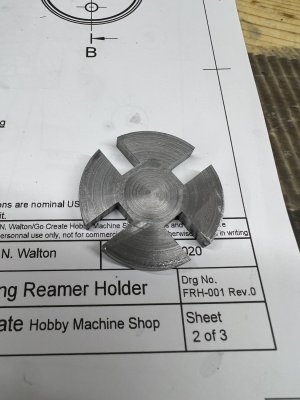

Heck yeah it qualifies.Not quite the same, but very similar, my floating chamber reamer holder.......does this count?

here it is on the cover of Machinist Workshop magazine

View attachment 470085View attachment 470086View attachment 470087View attachment 470088View attachment 470089View attachment 470090

IMHO anyway