- Joined

- Mar 26, 2018

- Messages

- 8,407

Good eye.Beeyootiful Jeff! Only comment - is the drill chuck threaded on to a hard shoulder? Only reason I ask is that I've made arbors with just the thread and no shoulder and been disappointed with the runout

I have a locking nut I need to thin down and make parallel on the surface grinder.

This should accomplish the locking and concentric requirements. I hope

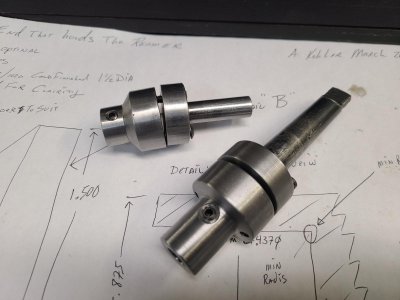

Edit: kind of like this>>>>>>>

Attachments

Last edited: