-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

B

Bill Gruby

Forum Guest

Register Today

Yes Bill.

"Bill"

"Bill"

B

Bill Gruby

Forum Guest

Register Today

Motor and Spindle mount mock up will be done tomorrow Mark. Should have the whole mock up done by Monday wake up. I making up for lost time. Kinda sore right now so I'm calling it a day.

"Bill"

"Bill"

B

Bill Gruby

Forum Guest

Register Today

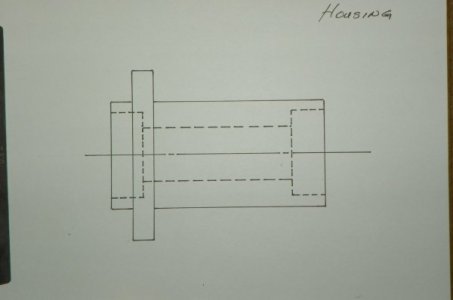

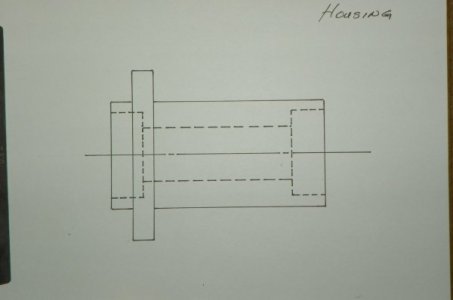

Tentative Spindle Housing Mark. Sending you one via snail mail. Yours will be dimensioned. I will leave the Spindle design up to you. Use the Lovejoy Coupling we discussed if you can. Feel free to make it larger in places. Bearings are up to you. Have fun. Just sent Mark. Delivery Date, Tuesday 5/24

"Bill"

"Bill"

Last edited by a moderator:

B

Bill Gruby

Forum Guest

Register Today

Time for the rest of you to put on the thinking caps. While I told Mark the bearings were his choice what would you suggest and why. Anything goes here. The motor is a 3/4 HP turning 3450 RPM.

Also, earlier in this thread there was a comment not to use the Lovejoy Coupling. Your thoughts on this also. Please add your reasons fore or against this Coupling.

"Bill"

Also, earlier in this thread there was a comment not to use the Lovejoy Coupling. Your thoughts on this also. Please add your reasons fore or against this Coupling.

"Bill"

- Joined

- Jul 30, 2012

- Messages

- 500

The only concern I can think of with the Lovejoy coupling is the backlash, or slop, in the connection. But this is a common coupling in CNC equipment, so my concerns are probably unfounded.

- Joined

- Jan 22, 2011

- Messages

- 8,031

That's a pretty wide open task, Bill. Only about 175 questions arise when making the optimum bearing selection.