B

Bill Gruby

Forum Guest

Register Today

You are right Tony, it's open to all so they could learn more about bearings and their application. Go for it fellas, class is in session.

"Bill"

"Bill"

Is there enough axial loading to justify that?I'm thinking precision angular contact. Maybe preloaded doubles on both ends of the housing?

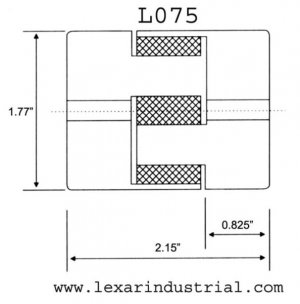

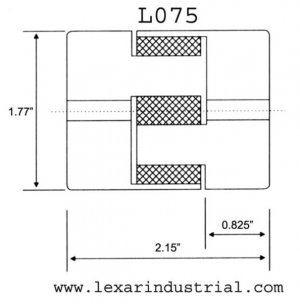

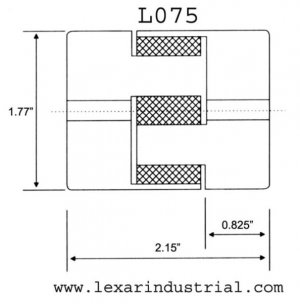

The only concern I can think of with the Lovejoy coupling is the backlash, or slop, in the connection. But this is a common coupling in CNC equipment, so my concerns are probably unfounded.