- Joined

- Dec 18, 2019

- Messages

- 6,464

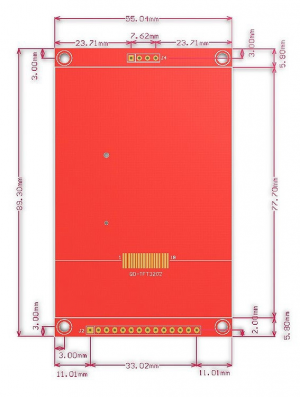

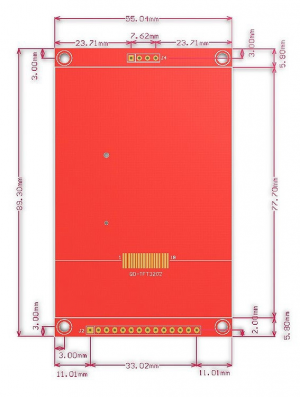

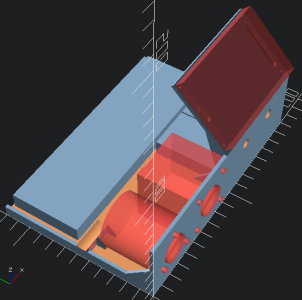

Due to my laziness, and also since the information should be posted in the right place, I posted on the PJRC forum asking about the 3.2" display. Paul (the owner) put up a mechanical drawing for the top view of the PCB. He just resells these, so that is what he has. The dimensions confirm my measurements, which had me puzzled initially. Metric drawings with a few odd dimensions, so guessing that the dimensions were nice even metric values would have been wrong. He posted it under his display web page at 320x240 display. I think the only missing major dimension is the hole size, which appears to be a scant 2 mm. By this I mean, a 2 mm screw can be screwed into the hole. Hope this helps. Here's a picture of it.