Welcome Spajo, good to see your comments here.

Early 70's about the only microcontroller available was the 4004. I did some projects with the 4004 and 4040 in about that time frame. It was fun trying to explain to the EE's at the small company how an assembler worked. ProLog had them hand-coding and typing in hex codes to a prom programmer, and they didn't know any better. Pretty soon they gave all the programming work to me and went back to their electronics.

I did a lot of projects with the AVR micros before Arduino came along. The Arduino environment did simplify things a bit. I use whatever is easy, haven't tried Platform IO yet. I'm not generally fond of big complex IDEs, I don't usually need the huge feature set and the next project may be something different and learning new IDEs is a distraction. But that's just me. The code should port and the real value is in the principles and techniques that work.

The bore on my PM-1228 lathe is 1.5" so I'm planning to drive the Omron from the gear on the spindle in some yet to be determined way. There are lots of examples of mounting Omron's on lathes already out there in various ELS and CNC projects. I haven't looked at encoders that could surround the entire spindle tube. I don't want to mod the lathe. I'd be interested in what you find and are thinking of doing there.

I did send the funds to PJRC for the display. We'll see if they ship quickly. Yes, they already added tracking info. They are quick.

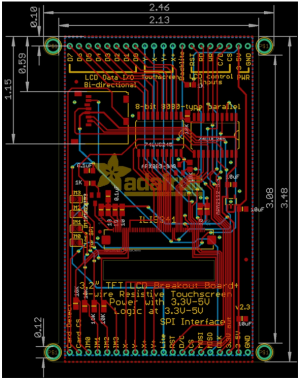

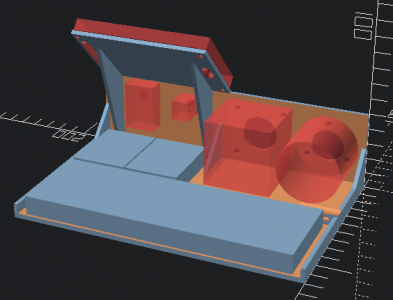

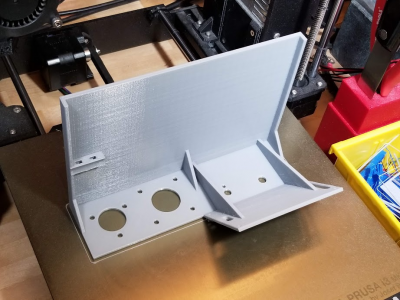

I made display mount CAD for both the PJRC and the Adafruit 3.2 TFT, but they overlap in a problematic way. Offsetting them enough to fix it might work, but it makes the display support wider.