Please do not take this as me preaching or the proverbial "I need to be right" or any of that goo, This is me discussing something near and dear to my heart. and my social skills are sometimes lacking.

I didn't mean to step on your curiosity, you kinda have to understand that I saw what you are doing and assumed you were trying to work out something on a project and thought I could help. A bit of History because you never know who you are talking to on the internet, I am actually a Sr. Piping Designer, I have designed Piping systems for process units Oil and Gas, Offshore drilling rigs, Ground support for Aerospace companies developing launch vehicles, Storage systems compression equipment and air separation for the Industrial gas industry (gas up to 15000 PSI and Cryogenics) etc.... so when I see a puzzle shaped like a pipe I cannot help myself

.

In the case of your puzzle, based upon what you told me, There are several likely reasons for the failure. First and number one is it a seamless tube? if not, it very likely failed at the seam, particularly if it was an extrusion with a dividing seam. Next, you are absolutely correct in your statement about the corners and if the bottom was flat in addition then the pressure in the middle of that flat would have applied enough distortion through its leverage at the corners to cause the tube to have uneven pressure along its long axis which would cause it to fail. a round cylinder is only good for high pressure as long as the hoop stress is even circumferential to the long axis, introducing an uneven stress will always lead to failure.

Just as a note, the threads are a great point for failure as well, threads introduce stress risers.

as far as Barlow's, it doesn't care what you call the cylinder nor How long it is, it works specifically based upon diameter, wall thickness and yield and it will tell you what the actual burst pressure is to within +/-5%. The one thing Barlow's doesn't factor in is poor manufacturing.

I hope there is something of interest there for you.

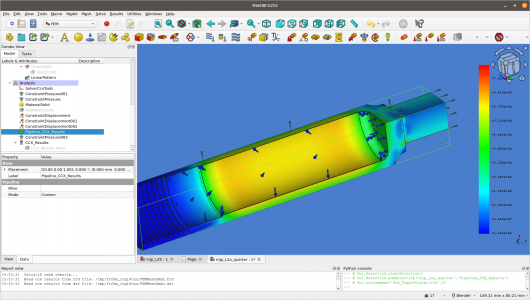

Pontiac428, I have Solidwork with Cosmos and you are correct, its good stuff and I am not very familiar with FreeCAD either.