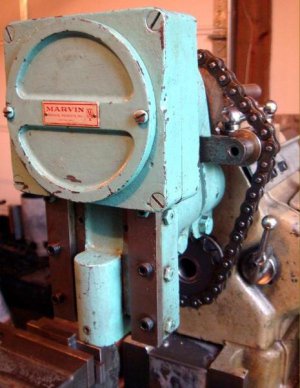

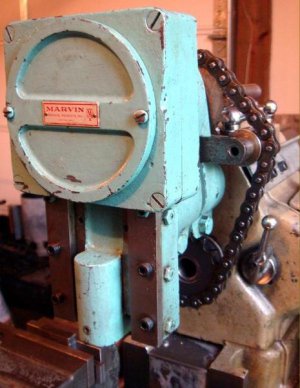

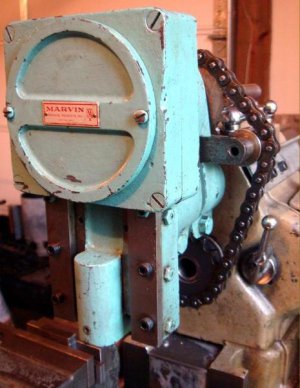

Marvin was the name of the original aftermarket vert head attachment for the Atlas Horizontal mill. In recent years the price of a complete and functional Marvin head was generally higher than the cost of most Atlas milling machines; they were just that high. However, a couple years or so back some small new upstart/machine shop knowing the desireability of the old Marvin attachment began offering spot on new replacements that were/are virtually identical to the origianl Marvin head. They were not cheap, but they were/are new, and vitually the same as the old highly coveted and priced Marvin attachments but at considerably less than the price of the old Marvin Heads. I have no idea if these are still currently being marketed and manufactured, if they are I suppose a simple google search would find them. The Marvin Vertical head was not the only product the Marvin company made though. As I recall they also made a slotter that was an aftermarket accessory for the Atlas 7B metal shaper as I recall.

I too noticed the taper, but for the life of me I cannot see how what is shown could be used as a vertical attachment for an Atlas milling machine.