-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bill M's Pm1340gt Setup

- Thread starter wrmiller

- Start date

- Joined

- Mar 21, 2013

- Messages

- 4,063

Ah...

Actually, this was taken at my friend's shop. He asked me to do some machining on this little part and I was standing in front of the Comet, staring at this thing trying to figure out how I was going to hold it properly to make the cuts when he says "hey" and I looked up to see a camera pointed at me. He just thought it was funny to see me standing there staring at this little part...

Actually, this was taken at my friend's shop. He asked me to do some machining on this little part and I was standing in front of the Comet, staring at this thing trying to figure out how I was going to hold it properly to make the cuts when he says "hey" and I looked up to see a camera pointed at me. He just thought it was funny to see me standing there staring at this little part...

- Joined

- May 8, 2015

- Messages

- 86

With all the great things I have been reading the past month or so in this and other threads on the PM forum, and especially how you guys certainly help each other out... I made the decision today to purchase the PM1340GT.

My grandfather always stated when purchasing something always buy the best value you can possibly afford... that way you won't regret buying something less down the road; And if it is some type of tool or equipment, you can't blame the tool... only your own understanding / knowledge / or skill of what input it needs from yourself to do whatever it is you want it to do...

S0 I have purchased a bit over my head as far as my grandfathers advice concerning my knowledge and skills - however I am looking forward to a great learning curve.

Matt states it's going to be a couple of months out - but that gives me time to start preparing my small workshop area in my garage.

Many thanks to all of you to give me the courage to start a journey I have thought about for years.

Dale

My grandfather always stated when purchasing something always buy the best value you can possibly afford... that way you won't regret buying something less down the road; And if it is some type of tool or equipment, you can't blame the tool... only your own understanding / knowledge / or skill of what input it needs from yourself to do whatever it is you want it to do...

S0 I have purchased a bit over my head as far as my grandfathers advice concerning my knowledge and skills - however I am looking forward to a great learning curve.

Matt states it's going to be a couple of months out - but that gives me time to start preparing my small workshop area in my garage.

Many thanks to all of you to give me the courage to start a journey I have thought about for years.

Dale

- Joined

- Mar 21, 2013

- Messages

- 4,063

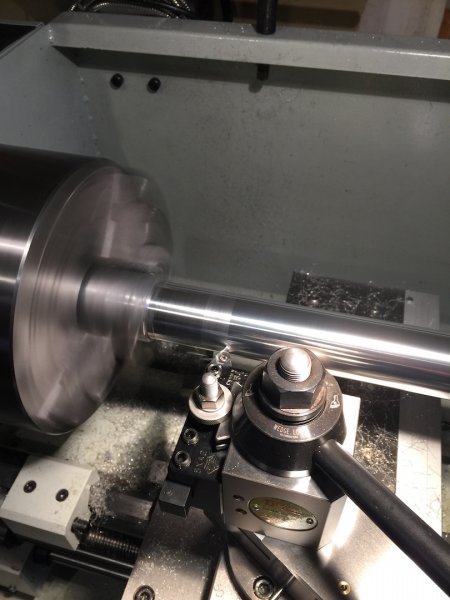

So I figured that it was time to check the level/accuracy of the lathe again. Last time, I used the old school method of leveling the bed, test cuts, then tweaking the tailstock end of the lathe to bring in the accuracy. Then Matt told me about the headstock adjusters. Doh!!

So this time I put the bed back to perfectly level (well, as perfect as a starett level and these old eyes can get), did some test cuts, and found that I was out about a thou over 9". This was a week or so ago. I let the lathe relax a bit and then today I decided to adjust the headstock. Took a few tries, but I ended up with the exact same reading over 9". Measured 4 times and came up with the same numbers. Figured that I couldn't do that again on a bet, so decided to call it good enough.

Love this lathe! Thanks to the guys here who unknowingly convinced me to step up. LOL...

So this time I put the bed back to perfectly level (well, as perfect as a starett level and these old eyes can get), did some test cuts, and found that I was out about a thou over 9". This was a week or so ago. I let the lathe relax a bit and then today I decided to adjust the headstock. Took a few tries, but I ended up with the exact same reading over 9". Measured 4 times and came up with the same numbers. Figured that I couldn't do that again on a bet, so decided to call it good enough.

Love this lathe! Thanks to the guys here who unknowingly convinced me to step up. LOL...

- Joined

- Sep 13, 2015

- Messages

- 61

then today I decided to adjust the headstock. Took a few tries,

Hey Bill, can you give a word or two and a pic of the adjustment turns you made on the screws to get the headstock/spindle alignment perfectly true to the bed? I bought this expensive test bar (probably unnecessary), and made a couple very minor tweaks to the headstock, but I wander if I'm doing it right.

There probably is a headstock alignment thread with plenty of details somewhere, but specifically, I want to hear a little more specifics from a PM1340GT brother specifically

RIO

- Joined

- Mar 21, 2013

- Messages

- 4,063

Hey Bill, can you give a word or two and a pic of the adjustment turns you made on the screws to get the headstock/spindle alignment perfectly true to the bed? I bought this expensive test bar (probably unnecessary), and made a couple very minor tweaks to the headstock, but I wander if I'm doing it right.

There probably is a headstock alignment thread with plenty of details somewhere, but specifically, I want to hear a little more specifics from a PM1340GT brother specifically

RIO

Hey Dude,

Well I can try...

My test cuts were showing the unsupported end to be one thou larger in diameter than the end near the chuck, over a 9" cut length. I visualized this in my head as the spindle pointing slightly inwards, or towards the backsplash. As the amount the spindle was off was pretty small, I did NOT loosen the headstock bolts, but instead I hoped that I could tweak the right-most bolt in the picture below just enough to bring the headstock/spindle in alignment with the bed. It took a few tries, as I went at the bolt easy at first to keep from overshooting and chasing my tail. First tweak, no change. Apply more grunt. Second try, no measurable change. Third try I gave the t-handle wrench a bit more grunt and probably only turned the bolt about 1/8th of a turn, and it came out perfect. Just blind luck I guess.