- Joined

- Mar 14, 2022

- Messages

- 696

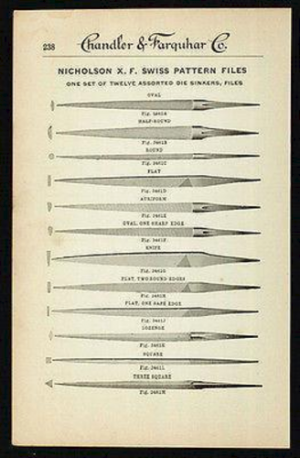

I'll supply the first thread drift. Any machined parts I've had a hand in years past, deburring was finished off with sanding belts with a fine grit. Being careful not to damage the machined finish. I now use a fine cut file; don't know what number it is. I'll wipe it down with Scotchbrite to further smooth it.