- Joined

- Jun 7, 2016

- Messages

- 361

I find it quite frustrating when I find a thread I am interested in and the thread comes to an abrupt ending part way through the project.

So in an attempt to avoid that for my fellow machinists.

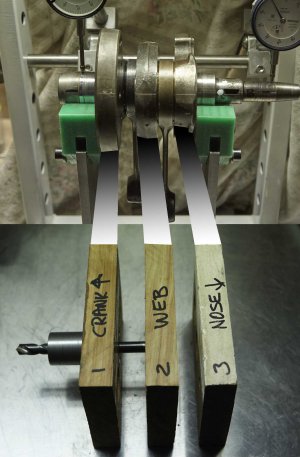

Here is the trueing stand with the latest additions.

These really sturdy and totally adjustable arms will allow me to put my dial gauges where ever I want them.

Still a few things to go but getting close to being ready for checking runouts.

Mal

So in an attempt to avoid that for my fellow machinists.

Here is the trueing stand with the latest additions.

These really sturdy and totally adjustable arms will allow me to put my dial gauges where ever I want them.

Still a few things to go but getting close to being ready for checking runouts.

Mal