Gentlemen:

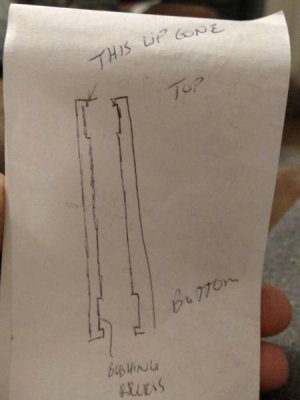

Getting close to having my 620 back together. Got all the gears in the head back in and closed up. Replaced X and Y lead screws and bushings. Had to make a new dial for one end that was missing... Only 200 indexes to take care of that with a rotating TopNotch boring bar.

In one of the questions in these threads, Yes, there is a .156 ball, spring, and set screw for 5 detents in the feed/neutral cylindrical rack. The screw is located on the lower right corner of the plate below the shifter. The hole is relatively deep so the set screw goes in 5 or 6 revolutions before it engages the spring.

Looking to seeing more on this, may need your help! I hate having to do everything the hard way. Looking forward to getting a peek at your machines.

Best regards, Gary