- Joined

- Nov 14, 2011

- Messages

- 27

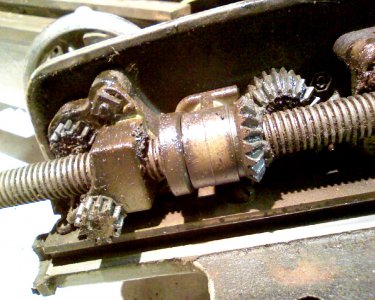

Your Lathe looks a lot like mine. I have 1946 Craftsman 101.07403 lathe. If yours is like mine, the model number is on the back of the ways, in the center. There is a nameplate there. There is also a serial number stamped in the top of front way, at the far right.couple pics the lathe is pretty grimey plans are to go through the whole thing and clean it up hopefully with all your guys help and experiance.

This how it looked when I found it on Craigslist.

And after some cleanup and paint.

I used some kerosene in a 5 gallon bucket to clear the crud off.

Then to further clean the rust off, I bought a 5 gallon bucket of evap-o-rust from Northern Tool. That stuff is amazing. Drop the part in, leave it overnight, wipe it off the next day. Or week, or month. It does not hurt to leave it too long.

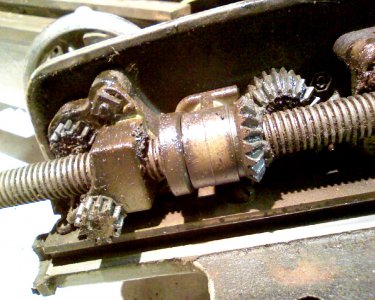

The Apron Before/After/Painted:

Hope that helps. If your lathe is the same and you have questions, ask. I may have hit the same problem.