- Joined

- Oct 16, 2019

- Messages

- 6,576

I do want to try metric as well as internal as I want to have the full repertoire of skills.Great looking work!

You'll find that the extension ratio for well supported stock to be even more critical in threading because the forces are pretty high. That second example would have benefited from some live center TS support.

You're really getting the hang of this! Congrats.

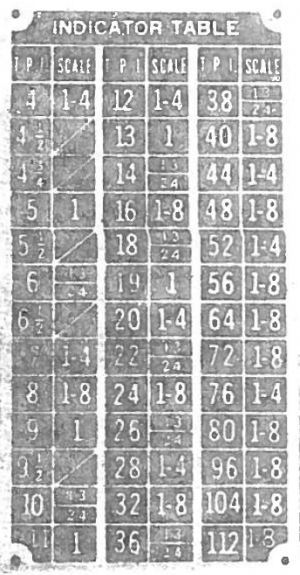

Next up is trying a metric thread. Requires you to have understanding of the change gears on your lathe and how to reverse the chuck out of the cut without undoing the half-nuts. Also in that bucket is internal threading and internal threading away from the chuck against a shoulder.

I did forget to reset the cross slide once last night and I just reversed back to the start so I didn't have to wait for my mark on the thread dial to come back around.

Come to think of it, if I pick a certain number on the dial do I always have to wait for the same number or can I engage on its opposite.

Say I start on the '1', can I also engage on the '3'?

Likewise start on the '2' and also engage on the '4'?