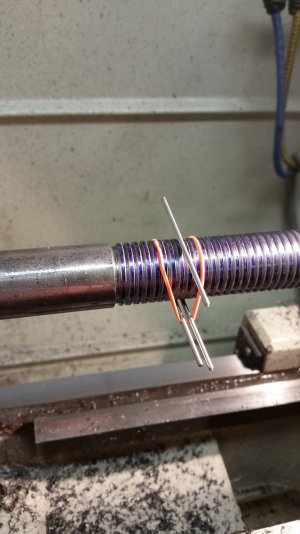

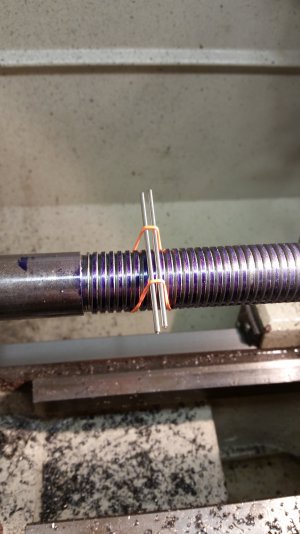

I do nearly all my measuring with wires. With some practice I certainly don't find them as difficult to use as most people claim. Certainly not as easy as a mic, but I never have issues with it. It also allows me to use my normal mic, calibrated against standards. You can't do that with a thread mic unless you have a thread master (which I don't).

But from a convenience factor, thread mics are great.

I worked for a while in a metrology lab and the gold standard is thread Go-NoGo gages. Very expensive to buy them for all your thread sizes and all tolerance classes. We probably had 15 sets of rings for each size of thread for various tolerance classes (ASME, DIN, ISO, etc). When I do production jobs, I will invest in the gages required for the job if the quantity is over a couple dozen. Very reliable to check that way.