B

BRIAN

Forum Guest

Register Today

Disaster Strikes.....

It seems that the interference I allowed was two large even after testing samples to see the amount of change .

Also it appears that placing a small part into large one, the heat mass immediately raises the temp of the small part before it can be pushed home.

So the two cages ended up being driven unmercifully into place with a big hammer the inlet cage ending up deeper than was intended causing distress to the area in the head where it sits, both cages broached out a sliver of material from the bores in the head. After the event I found no change to the length of the cage, or any evidence of distortion to the head apart from the inlet cage being .5 mm low in it's bore.

Deciding that the head was probably ruined anyway, I reprofiled the area of the head around the low cage with the flexy grinder and a diamond burr then continued to bore out the throat's and lightly cut the valve seat's , Just to prove to myself I had not got it all wrong .

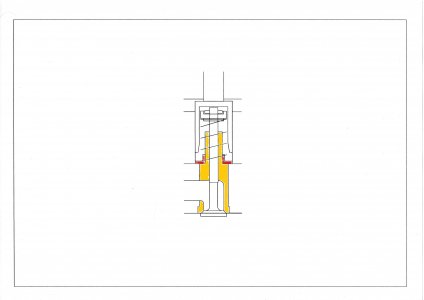

You can see the reprofiled area of the head around the cage nearest to the camera.

You can see the reprofiled area of the head around the cage nearest to the camera.

Now I have to rethink my method so I do not ruin another head. so it's time out on the valve work for the moment.

Live and learn, Brian.

It seems that the interference I allowed was two large even after testing samples to see the amount of change .

Also it appears that placing a small part into large one, the heat mass immediately raises the temp of the small part before it can be pushed home.

So the two cages ended up being driven unmercifully into place with a big hammer the inlet cage ending up deeper than was intended causing distress to the area in the head where it sits, both cages broached out a sliver of material from the bores in the head. After the event I found no change to the length of the cage, or any evidence of distortion to the head apart from the inlet cage being .5 mm low in it's bore.

Deciding that the head was probably ruined anyway, I reprofiled the area of the head around the low cage with the flexy grinder and a diamond burr then continued to bore out the throat's and lightly cut the valve seat's , Just to prove to myself I had not got it all wrong .

You can see the reprofiled area of the head around the cage nearest to the camera.

You can see the reprofiled area of the head around the cage nearest to the camera.Now I have to rethink my method so I do not ruin another head. so it's time out on the valve work for the moment.

Live and learn, Brian.