You don't need to be too fixated on when to save the design, you can save it at any point. The one caveat is if your computer crashed and you didn't save your design, you will lose everything since fusion does not have recovery files that I have found. I learned that the hard way. That might be why the videos you saw all say to save it right away.

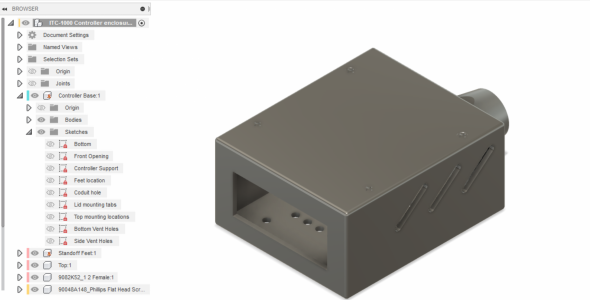

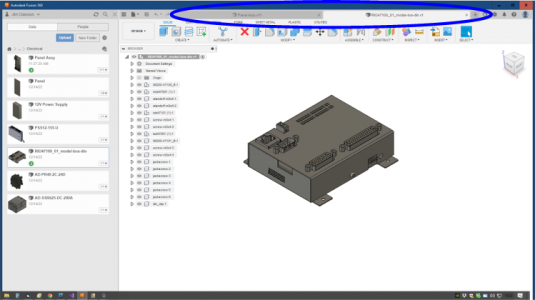

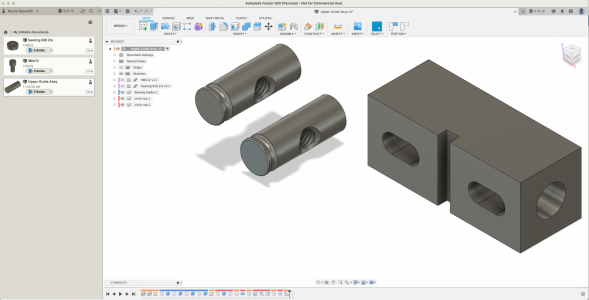

The way I set things up, take a lathe for example, a new design would be the lathe, the parts of the lathe would be the components. You can group the components in an hierarchical way. Take the headstock, that could be one component with the bearings, spindle, gears, etc as sub components. The carriage could be a component with the cross slide parts as components underneath it. The tail stock could be a component with all its parts as sub-component. Something like a motor that could be used elsewhere would be it's own component so that you can save that to use in other designs. How to do that is for another day when you are more familiar with the program.

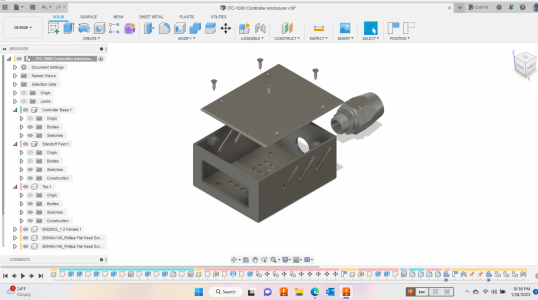

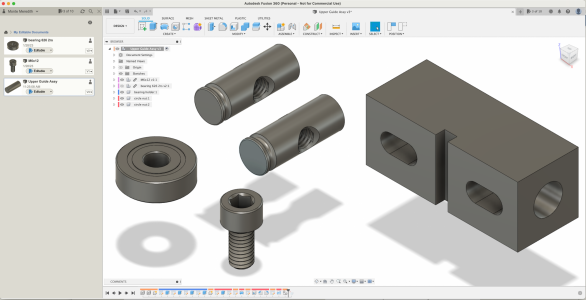

Something I like to go is group my hardware under a hardware component so that they are all in the same place. My top level component would be named hardware, and each screw, nut, etc would be a sub component within that hardware component. For things that might be used in multiple places, that helps keep them organized. I use the McMaster-Carr menu item to add the hardware, bearings, etc to my models, it doesn’t matter if that is where you will actually buy the parts, the important part of that is if you create a diagram of off the parts in the complete assembly, you will know how many of what to order.

Once you have your model designed, then you can create drawings of each component (part) you are going to make. It might seem overwhelming at first, but once you get used to it, it’s very powerful. When I started using Fusion, I followed along with a series of videos that goes step by step by Arnold Rowntree and was able to get proficient very quickly. Lars Christiansen is another good one to follow as has already been recommended, but I think he changed jobs and stopped making new videos. Even though some of the videos are a bit older, the ideas are the same, but you might need to search a bit more since the menus may have changed somewhat.