- Joined

- Mar 26, 2018

- Messages

- 2,724

Whooo!!! nice workIT WORKS!!!! The MPG Pendant is finally working!! E-Stop on the MPG Pendant is also functional!

Whooo!!! nice workIT WORKS!!!! The MPG Pendant is finally working!! E-Stop on the MPG Pendant is also functional!

You rock!Whooo!!! nice work

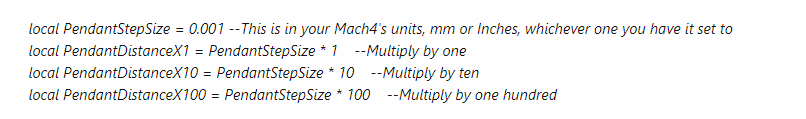

Just a quick recommendation. I'd recommend X1 to be set for 0.0001", X10 to be set for 0.001" and X100 to be set for 0.01". Set the jog speed and acceleration in the smoothstepper config for the MPG to as high as your machine can do.You rock!

Nothing like the sound of stepper motors in the morning

Just a quick recommendation. I'd recommend X1 to be set for 0.0001", X10 to be set for 0.001" and X100 to be set for 0.01". Set the jog speed and acceleration in the smoothstepper config for the MPG to as high as your machine can do.

The reason for this is avoiding windup on the knob where you spin it a long distance, and your machine lags behind and overshoots where you want to go. It is better to have each click on the MPG move a smaller distance and then you spin the MPG faster.

Just my recommendation!

EDIT: This change is made in the LUA code, "local PendantStepSize = 0.0001"

View attachment 376799

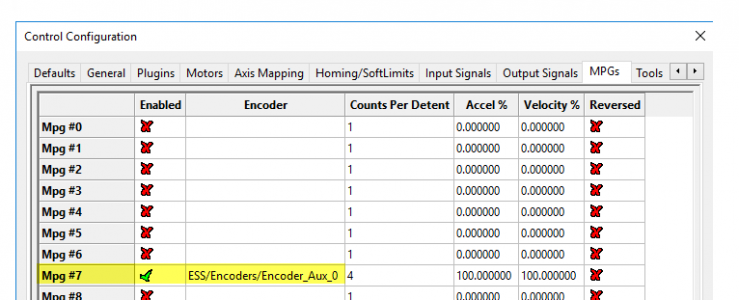

These should be set to velocity 100%, Accel 100%

View attachment 376800

You'll also benefit all over from maximizing the acceleration settings for each of your axis motors in the Motors tab. This will affect your machine performance and cycle time much more than increasing the top speed. You can set up some repeatability tests to verify you are not losing steps.

Nice. Sounds like your settings are correct - just try to play with the motor settings to maximize the acceleration as much as your motors can handle. If you hit the limit where they stall, back off 20%.Got it... I have it now at:

local PendantStepSize = 0.001

I will change it to:

local PendantStepSize = 0.0001

I believe that I have Accel % and Velocity % set to 100%. But I will double check as well as I do not recall changing anything on that field... hummm...

I am currently using an old, very old, laptop... It works, but slow as heck... But it works. It has the RJ45 port integrated and has been able to connect to the board without any issues.

The newer machine that I have is very fast but it has a USB adapter for the RJ45 connector and I have not been able to make that one communicate with the board. Will tackle that in a few weeks... for now I just want to make sure everything else is setup correctly.

Will be right back, let me check these settings and make the changes.

Nice. Sounds like your settings are correct - just try to play with the motor settings to maximize the acceleration as much as your motors can handle. If you hit the limit where they stall, back off 20%.

I'll warn you that USB -> RJ45 adapters are known to not work with the ESS. Call Warp9TD and see if they have any recommendations. Mach 4 is not very CPU intensive. I run mine on an industrial PC with an Atom processor (think Kindle) with 2GB of RAM. Probably half of the minimum system settings and it runs great. I'd look for a cheap windows 10 PC with maybe an i3 processor, 4GB of RAM, and an integral Ethernet port.

A USB Type C to RJ45 might work OK since the protocol is native to the port (that's how docking stations work). USB Type A to RJ45 sort of fakes the ethernet connection and is not OK for demanding applications.

Do you already have a computer for CAD/CAM? If not, it might be worth getting a laptop that can run the CNC and run whatever CAD CAM you'll use. Might be a bit more expensive but save you from getting two machines.Got it. Was trying to use an old, but faster notebook that I had. After reading your comment, not going to even bother any more to try to make it work... I will find something with an integrated ethernet port.

Made the change to the local PendantStepSize parameter. Less scary to move on the X100 now... hehehehe

I forgot to check the Motors settings... will play with those next.

Now searching for an inexpensive notebook to replace this dinosaur...

Do you already have a computer for CAD/CAM? If not, it might be worth getting a laptop that can run the CNC and run whatever CAD CAM you'll use. Might be a bit more expensive but save you from getting two machines.

Got it - yeah a basic laptop with an ethernet port should be perfect. I'd look for an i3 with 4Gb RAM and a 128Gb SSD. If it is Win10, then it should boot in 10 seconds flat.About 6 years ago I built a computer for image and video rendering. At the time, my daughter had started college. She is currently finishing her masters in character animation... She now has her own computer and Wacom MobileStudio, Wacom tablet, etc... so she no longer is using the tower I built...

It is a graphics processing monster... But it is huge...I wanted excessive cooling and placed everything in a large tower with 8 fans, liquid cooling, 6 cores Intel i7 4930 chip, 32 gigs of RAM, 2 - 1T SSD, NVidia GEFORCE RTX 3080 Ti with 12 Gig video card (since I built several years ago, I have been upgrading the video card as better ones come out)... Not something I am going to move to the garage.

It is where I have the Fusion 360, Simplify3D, ZBrush, you name it... 3D printer is connected to it as well...

A cheap notebook, dedicated to the milling machine, will be good for now... Money better spent in tools for the lathe and milling machine

Right now I am just not shutting down the old notebook...the time it takes to boot up... man... lol