- Joined

- Aug 6, 2015

- Messages

- 3,886

Well... was out a few weeks... Friend needed help and invited me to be part of his crew for his runs at Bonneville Salt Flats... got back Friday and we had family arriving that night... so it has been good, but no work on anything else.

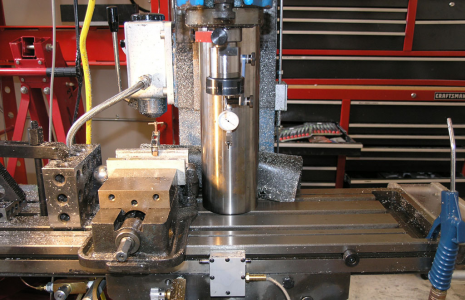

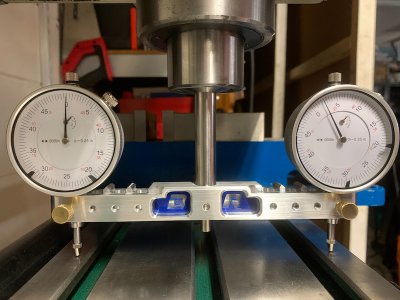

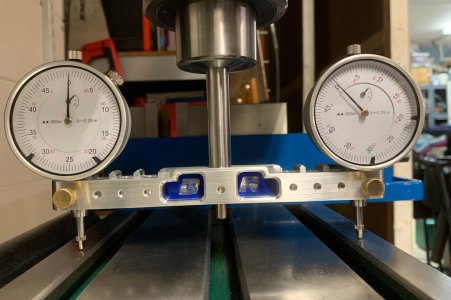

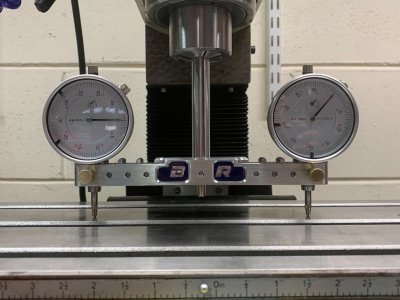

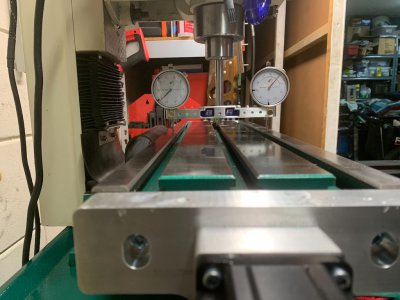

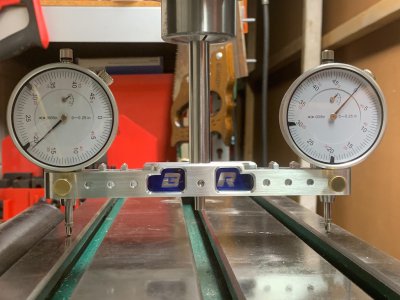

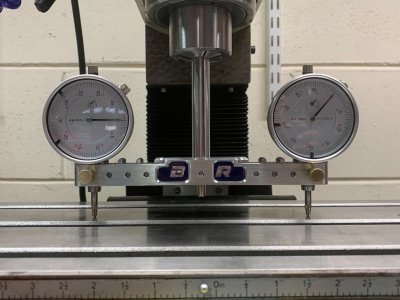

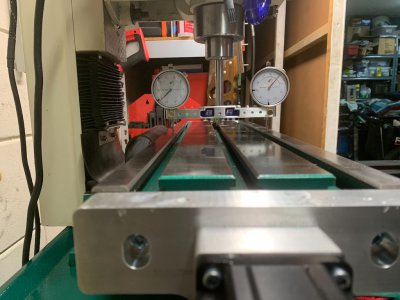

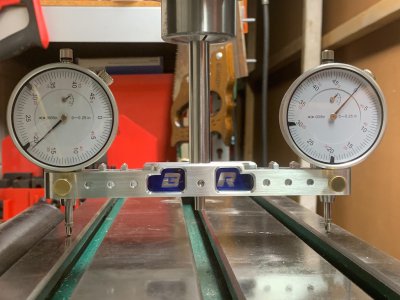

I did managed to sneak into the garage tonight to test the tramming tool... Made the adjustments and this axis is done...

Now, how do I adjust the column?? There is no adjustment that I could see... Do I have to loosen the four bolts and insert feeler gauges in there to get it where I want it? Or is there a better way to do this?

Doing a search in the forum to see what others have done. Also checking YouTube for any videos on this as well.

A few threads on this;

www.hobby-machinist.com

www.hobby-machinist.com

I did managed to sneak into the garage tonight to test the tramming tool... Made the adjustments and this axis is done...

Now, how do I adjust the column?? There is no adjustment that I could see... Do I have to loosen the four bolts and insert feeler gauges in there to get it where I want it? Or is there a better way to do this?

Doing a search in the forum to see what others have done. Also checking YouTube for any videos on this as well.

A few threads on this;

PM932- PDF Gearhead Tilting Modification.

Adjustment/tramming of the gearhead after tilting for milling operation (or procedure for oil change as described in owners manual) is less than desirable IMHO. I would like to share my modification with all other owners of PM932 and other mills of similar design. Please note that this...

www.hobby-machinist.com

www.hobby-machinist.com

Last edited: