-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

G0704 CNC Conversion (yes, another thread on this :) )

- Thread starter wachuko

- Start date

- Joined

- Mar 26, 2018

- Messages

- 2,724

Hi @wachuko!

I’m a fellow G0704 guy on this site. Converted mine in 2013 first to a Hoss machine style design with dual shaft Nema 23 steppers, then recently to AC servos. I’ve done the works on this machine over the years (far more than necessary) and I’ve had a blast.

Happy to chat, share ideas, answer questions , etc. as you go through your conversion. You’ll learn a ton as you go along and hopefully have a lot of fun too.

-Mike

I’m a fellow G0704 guy on this site. Converted mine in 2013 first to a Hoss machine style design with dual shaft Nema 23 steppers, then recently to AC servos. I’ve done the works on this machine over the years (far more than necessary) and I’ve had a blast.

Happy to chat, share ideas, answer questions , etc. as you go through your conversion. You’ll learn a ton as you go along and hopefully have a lot of fun too.

-Mike

- Joined

- Aug 6, 2015

- Messages

- 3,885

Hi @wachuko!

I’m a fellow G0704 guy on this site. Converted mine in 2013 first to a Hoss machine style design with dual shaft Nema 23 steppers, then recently to AC servos. I’ve done the works on this machine over the years (far more than necessary) and I’ve had a blast.

Happy to chat, share ideas, answer questions , etc. as you go through your conversion. You’ll learn a ton as you go along and hopefully have a lot of fun too.

-Mike

Mike, thank you. I do have a few questions and pretty sure many mores will come up as I start the build... right now I am diving into videos and build threads.

One question that I have is what tool holder are you using?? Looking to make life a bit easier when changing tools... something that allows quick swap would be ideal. Guessing this will be even more important with a CNC setup...

- Joined

- Aug 6, 2015

- Messages

- 3,885

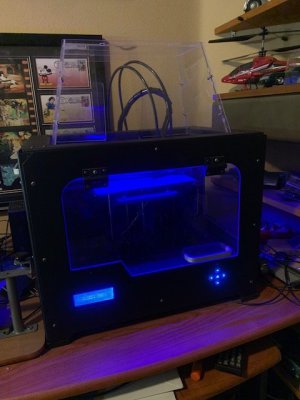

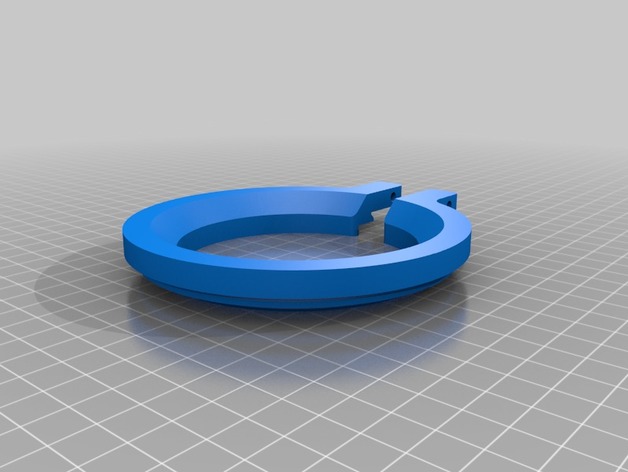

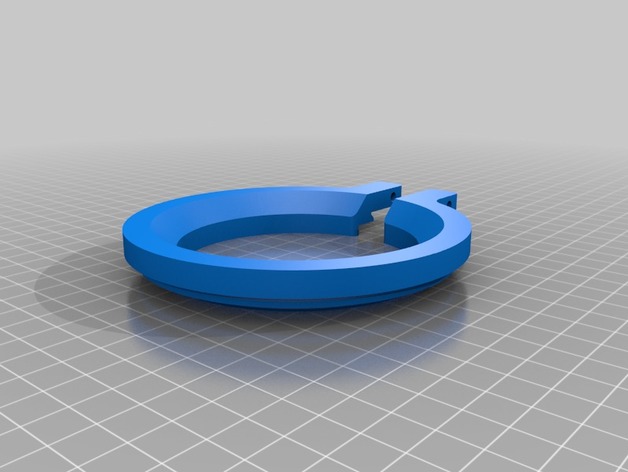

LED holder is done... LEDs should be here in a week or so...

www.thingiverse.com

www.thingiverse.com

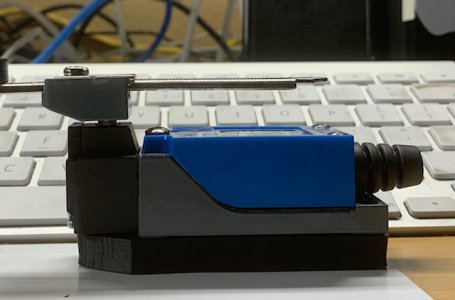

Now that I know that the printer is working fine, on to print the mounts for the limit switches...

G0704 LED Ring by charliexx

I slightly modified Pat's original design since i had one different ring light for the top light i used a (110mm) but its thinner https://www.amazon.com/gp/product/B00W6ZXROS/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 and for the bottom light, same as Pat's original.

Now that I know that the printer is working fine, on to print the mounts for the limit switches...

Last edited:

- Joined

- Mar 26, 2018

- Messages

- 2,724

Mike, thank you. I do have a few questions and pretty sure many mores will come up as I start the build... right now I am diving into videos and build threads.

One question that I have is what tool holder are you using?? Looking to make life a bit easier when changing tools... something that allows quick swap would be ideal. Guessing this will be even more important with a CNC setup...

I have standardized on the Tormach Tooling System - TTS (Short 3/4" shank and master collet system). Tooling is relatively cheap, and it fits the existing spindle. It is an investment to get into, but once you have the CNC done, the ability to save your tool offsets in a table is super valuable. I have 24 ER20 holders, a 2" boring head, a Tormach brand edge finder, and a 5/8" drill chuck setup for TTS. While not strictly necessary for using TTS, my addition of a pneumatic drawbar was one of my favorite modifications. It just works and it is super fast to change tools.

I purchased almost all of these from China. Mixed quality, but the seller always made it right if I had issues. You save about 50% over Tormach pricing doing it this way, but it takes a little diligence on your part to inspect the incoming products. I detailed this starting on post #79 of my build thread. I did a short review of the import chucks on post #95 and #99.

G0704 CNC AC Servo Rebuild (Picture Heavy)

Got some new bolts in the mail and got the spindle assembled. Unfortunately, working just from a CAD model bit me again and not all of the mounting holes on the top of the spindle line up (guess the Chinese factories put holes wherever they please). I'm hoping I can open up the counterbored...

www.hobby-machinist.com

www.hobby-machinist.com

- Joined

- Aug 6, 2015

- Messages

- 3,885

I have standardized on the Tormach Tooling System - TTS (Short 3/4" shank and master collet system). Tooling is relatively cheap, and it fits the existing spindle. It is an investment to get into, but once you have the CNC done, the ability to save your tool offsets in a table is super valuable. I have 24 ER20 holders, a 2" boring head, a Tormach brand edge finder, and a 5/8" drill chuck setup for TTS. While not strictly necessary for using TTS, my addition of a pneumatic drawbar was one of my favorite modifications. It just works and it is super fast to change tools.

I purchased almost all of these from China. Mixed quality, but the seller always made it right if I had issues. You save about 50% over Tormach pricing doing it this way, but it takes a little diligence on your part to inspect the incoming products. I detailed this starting on post #79 of my build thread. I did a short review of the import chucks on post #95 and #99.

G0704 CNC AC Servo Rebuild (Picture Heavy)

Got some new bolts in the mail and got the spindle assembled. Unfortunately, working just from a CAD model bit me again and not all of the mounting holes on the top of the spindle line up (guess the Chinese factories put holes wherever they please). I'm hoping I can open up the counterbored...www.hobby-machinist.com

I remember seeing your thread and thinking, wow, what this guy is doing is waaaayyyy out of my league

I have to say, you have done a lot with your machine. That pneumatic drawbar is awesome. Something that I will need to look into after converting the machine. That is one of the most tedious tasks with this machine...if it can be improve with something like that, I want to do it!

Another question... on the software... should I go with Mach3 or Mach4-Hobby? I see that you have experience with both. I just checked pricing and they are about the same price...

Lot's to read and learn.... thanks again.

- Joined

- Mar 26, 2018

- Messages

- 2,724

I remember seeing your thread and thinking, wow, what this guy is doing is waaaayyyy out of my league. I only looked at the first few pages in the thread and realized that I had a lot to learn. So I have more reading to do. Thank you for jumping in here to provide guidance.

I've been doing this for a long time and I often do things "because I can". Hopefully it isn't overwhelming and I am very much happy to chat and answer questions! Also happy to share design, drawings, etc.

I have to say, you have done a lot with your machine. That pneumatic drawbar is awesome. Something that I will need to look into after converting the machine. That is one of the most tedious tasks with this machine...if it can be improve with something like that, I want to do it!

Love the PDB. One of the best mods. Tool changing is tedius. TTS even without the PDB makes it much faster, but pushing a button and having your tool fall out is just so nice.

Another question... on the software... should I go with Mach3 or Mach4-Hobby? I see that you have experience with both. I just checked pricing and they are about the same price...

100% Mach 4 hobby. Don't even consider Mach 3. There are other software packages like LinuxCNC, UCCNC, and others that people can comment on, but I am all for Mach 4. Works great out of the box, lots of flexibility to configure for your needs later on. I highly suggest getting a good motion controller. Ethernet Smoothstepper is my recommendation.

Mach 3 is old and buggy. It is only being sold for people who don't want to relearn a new software. You really can't get support for it either.

- Joined

- Aug 6, 2015

- Messages

- 3,885

...100% Mach 4 hobby. Don't even consider Mach 3. There are other software packages like LinuxCNC, UCCNC, and others that people can comment on, but I am all for Mach 4. Works great out of the box, lots of flexibility to configure for your needs later on. I highly suggest getting a good motion controller. Ethernet Smoothstepper is my recommendation.

Mach 3 is old and buggy. It is only being sold for people who don't want to relearn a new software. You really can't get support for it either.

Excellent, thank you.

And yes on the smoothstepper. I ordered that yesterday from Amazon - Ethernet SmoothStepper CNC Motion Controller by Warp9 Tech Design Inc. Should be here before the end of the month.

- Joined

- Aug 6, 2015

- Messages

- 3,885

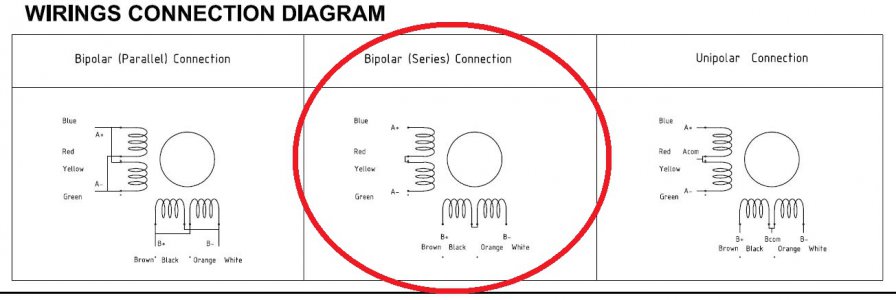

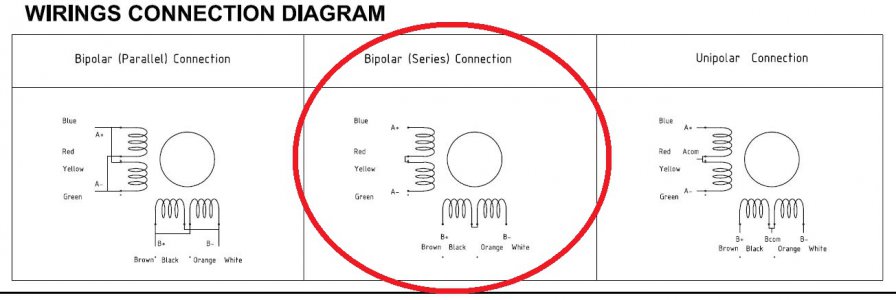

Because I wanted dual shafts in all motors (to be able to manually turn them), and because Automation Technologies did not have one with 4 wires, had to buy one with 8 wires (NEMA 34 640 oz-in Stepper Motor (KL34H280-45-8B) Dual shaft ) ... Just documenting the wiring setup that I need to do to make it into a 4-wire unit.